Everything you need to know about fabric district

The area is a modern alternative to the classic natural fabrics used in light industry. In the article we will consider the description, history of appearance, characteristics, types and applications of the material.

What it is?

The region is a product of a weave of chemical fiber. It is a light and elastic textile with an unusual texture. Its characteristics are the same as those of other natural counterparts. The title of the material consists of 2 words. Ray means "sparkle" and the ending on is similar to what a cotton has. In the professional vocabulary, international legislation has enshrined the name of the region as viscose silk. It has a smooth texture that is pleasant to the touch. It shimmers in the light, changing shade under different lighting conditions.

It is considered a dirt-repellent material that has no antibacterial properties.

According to its properties, it is called the "golden mean" between natural and artificial fabrics. It is optimally strong and wear-resistant, has a small thickness and medium breathability. The textile is soft, with a matte or semi-matte front side, embossing, relief patterns. Upon closer examination, the threads have lobar grooves with a transverse rounded section. Certain types of fabrics imitate the texture of wool, silk, cotton and linen.

History of origin

The district appeared in 1844. The new chemical process was described by the English scientist Mercer. Its essence consisted in the regeneration of an aqueous copper-ammonia cellulose solution. The method has been actively used since 1857 by E. Schweitzer. From 1858 the work was continued by I. Schlossberger and M. Kramer. In 1892, they learned how to turn the solution into fiber.

This method began to be actively introduced into the industry. This process was quite complicated. It consisted of 2 stages, each of which consisted of 3 consecutive steps. To obtain 100% of the area, wood pulp was produced. The work began with the digestion of wood in calcium hydrogen sulfate. The process took about 24 hours under pressure. The resulting thick mass was diluted in water and fed to a conveyor. After drying, it was cut into thin sheet plates. They were then treated with a chemical to form cellulose santogenate.

At the second stage of fabric production, the resulting substance was transformed into a spinning solution under the action of special chemicals. Later he entered the die. Passing through a plate with tapered holes, the solution was fed into the acid tank. This is how the viscose fibers were formed. The fabric made from them was silky.

The area is often referred to as artificial silk. Spruce and pine wood was used for its production. Today, recycled linen and cotton waste is used in production. Modern material may contain inclusions of other fibers (polyester, lycra).

Thanks to repeated changes in production technology, it was possible to obtain a fabric that is beautiful in terms of external indicators.

Its texture was determined by the shape of the fibers themselves, formed on different types of spinning equipment. Based on this, the fibers were flat, round, arched. Depending on the characteristics of the production, the fiber could be produced colorless or dyed in the mass. Due to artificial processing, it became inert to moths. The material is not easy to work with, it slips when cut, which causes the risk of cutting out uneven parts. The finest threads made from viscose fibers are used in machine embroidery.

What is the material?

The district has several types of weaving of fibers. It is available in silk, satin, crepe, knitted and twill. The way the threads are woven determines the properties of the material, its tensile strength and elasticity. The material also differs in composition. The more acetate and polyester fibers it contains, the more pronounced the satin sheen of the fabric. The fewer additives, the higher the crease. The region, consisting of viscose and natural silk, is especially decorative. Its texture is velvety, patterned, silky. In this case, the color of the woven pattern can contrast with the main background.

The fabric is made from different threads, which are textile, cord, staple. Threads of the first type are thin and smooth. They make a material that deforms after washing and tears easily. Cord fabric is slightly stronger and denser. It stretches well on the duck. The staple type of thread allows you to create textiles with the highest density. The staple threads are short, due to which the fabric acquires elasticity. These fabrics contain up to 96% recycled cellulose and cotton fibers.

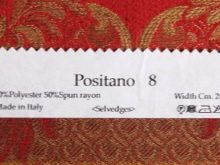

The textile fabric is heterogeneous. The technical type has similar qualities, but it is slightly denser and not as elastic. The material itself is 100% and combined. Common components of recycled rayon fibers are cotton and polyester. Their percentage can be up to 40% or more.

The district differs in grade, which is the first, second and highest. Materials made from these fibers are labeled as "Tencel", "Bamboo", "Modal". The difference between the types is the way the raw material is processed. Some options are dense, others can shine through in the light. Materials are divided into costume and dress materials.

There are 2 types of textiles according to the method of fabric production. The traditional district is made from simple rayon fibers. Spun rayon - from twisted. By the type of staining, the material is monochromatic and printed. The palette of shades is quite diverse and includes many tones.In addition to white, black, gray and natural colors, there are many pastel, bright, dark noble shades in it.

Varieties with a pattern are divided into thematic groups. Classic options are striped fabrics, geometric patterns, polka dots. Animal print (leopard, snake) is popular. For dress fabrics, the application of plant and flower motifs is characteristic. For children - characters from popular cartoons and cute animals.

Thicker fabrics are usually plain. The lungs can be decorated with a monogram, floral-curl pattern. The size of the pattern varies. For dress fabrics, medium-sized repeating images are usually used. Home textiles are mostly printed in medium size.

Often, the same drawing is performed on a background of different colors. Thus, the number of colors in the lines of each theme increases.

Popular designs are lilies of the valley, tropical leaves, wildflowers. In addition, textiles can have coupon colors. In this case, the element of the picture is larger on one side than on the other. The width of the canvases can be 140, 150 and 160 cm. The length is usually indicated in yards (1 yard is equal to 0.914 m). Sale is carried out in bulk and cut. You can buy fabric in the store and online.

Basic properties

The area has its pros and cons. It has high thermal conductivity. It can store and conduct heat, and its thermoplasticity can reach 100-120 CO. The length of the fibers is 3.4-6.5 cm. The tensile strength corresponds to 0.13-0.15 mN / tex. The material is resistant to water, benzene, gasoline. However, it burns well, giving off the characteristic smell of burnt paper and leaving an ashy ember that can be rubbed with your fingers. Textiles can have different densities.

Methods for measuring fiber thickness vary. In our country, linear density is measured by the ratio of the mass to the length of the thread in tex (T). Its weight with a length of 1 km is 11.1 g. The specific weight of textiles is 10% more in comparison with the natural silk analogue. The natural moisture values are close to silk, which is twice as strong as the region.

Wet and wet fabric loses its strength up to 60% or more of the original values. This feature forces products to be washed from the area in a delicate mode. According to the indications of elasticity, the fabric is 2 times inferior to silk. Varieties that have added lycra stretch better. Together with the improvement in tensile properties, they acquire strength. The material can be perfectly painted in any color, retaining its original brightness for a long time. Due to this, it looks expensive, bright and aesthetically pleasing.

The material is hygienic and does not provoke allergies, does not irritate the skin. Its price is less than that of traditional silk. Products made from it are comfortable to wear and do not disturb the air balance. Due to the demand, the material is often faked.

Counterfeit products are more electrifying. It is also less breathable. Despite being treated with chemicals, it does not melt when burned.

Manufacturers and prices

The area produces trade marks from different countries. High quality products are supplied to the domestic market by manufacturers from Russia, Italy, Korea and China. In the lines of matter, there are options for budget and expensive types. The region's production is widespread in Uzbekistan.

The cost of the material depends on the type of raw materials used and production costs. The starting price of textiles made from pure viscose is 250 rubles. An analogue containing polyester fibers is sold at a price of 500 rubles. The fabric, which contains 20% of cotton fibers, has a cost of 400 rubles per 1 running meter.

More expensive than other types are fabrics made of viscose and silk fibers, the percentage of which is 60:40. Their price for 1 m can be up to 1,500 rubles. Most of all you have to pay for fabrics from Italian suppliers.In the retail sale of companies, the price for 1 running meter of viscose-silk material can reach up to 7,000 rubles. In the online format, it is sold on various trading platforms.

For example, it can be ordered at retail on AliExpress, in the La Bottega dei Tessuti store, in the Torgovaya Stavka, on the Korea Fabrics website.

Application

Due to the different diameters of the threads, lightweight and outerwear is sewn from textiles. A considerable range of products from this material is presented on the domestic market. These are casual and elegant dresses, blouses, trousers, capes, shawls, scarves, sundresses, tops, pareos. The technical varieties are suitable for the lining of outerwear. Without them, tailoring of jackets, jackets, trousers, vests is not complete.

It is used in design houses, making the best models for the catwalk. Textile is a material for sewing bed linen. Sets for children and adults are sewn from it, consisting of pillowcases, sheets, duvet covers. Based on its density and design, it is suitable for sewing underwear, pajamas, nightgowns. Despite the differences in appearance and composition, dense varieties are used in the production of coats and jackets.

The fabric is recognized as one of the best alternatives to many curtain counterparts. Thanks to this, thick curtains, light curtains and curtains of various cuts are sewn from it. It makes beautiful pillowcases for decorative pillows. At the same time, they are often complemented by various decor, which is selected taking into account the density of the fabric, its texture and colors.

Regular, pile or quilted bedspreads and napkins for interior decor, carpets of different densities are made from the area. The area is used for the production of faux fur, which in turn is used to create spectacular furniture covers. Dense types of textiles can be used as decorative panels. Soft toys and towels are made from textiles.

It produces high-quality cleaning wipes that perfectly absorb water and cope well with dust and dirt.

Care rules

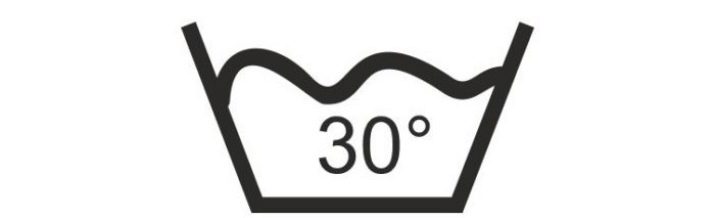

Considering the fact that the area shrinks during washing and is prone to deformation, it must be washed correctly. The priority method is hand wash. In this case, the effect on the fibers is minimal. Washing in the drum of the washing machine takes half an hour. It is advisable to wring out products from the material at minimum speed. Otherwise, the material may wrinkle severely. The detergent is selected according to the type of wash.

Powders for hand and machine handling vary in foaming. The wrong choice will result in incomplete rinsing of the fabric. The maximum allowable temperature is 30 degrees. If you wash things in hot water, irreversible deformation cannot be avoided.

To get rid of stains, use special products. To check the effectiveness of a product, it is applied from the wrong side in an inconspicuous place. If after 15 minutes the color does not change, you can treat the problem area. You need to dry the products in a natural way. Artificial drying on heating radiators and heaters is unacceptable.

Do not dry viscose silk items in a drying cabinet. Acceleration will disrupt the structure of the fabric, making the fabric rough. If there is any doubt about the strength of the material, instead of spinning it after washing it is put on a towel. So they get rid of the main water, then dry the product in an upright position.

Depending on the thickness, the material has a different level of wear resistance. You need to iron it through a thin cotton fabric. If the fabric has a lot of creases and folds, they need to be steamed. To do this, you can select the appropriate iron mode or moisten the fabric with a spray bottle. You can iron textile products from the wrong side.

After ironing, you need to store things made of textiles on hangers, otherwise folds and creases will form again at the places of folding. If the apartment is damp, it is necessary to frequently ventilate the room. Some types of material are prone to snagging.

It is important to handle the products with care. This will help extend the life of things.