Description of the cloth and the area of its use

Woolen fabric with unique properties is widely used in various spheres of life. Dense and strong material, which looks like felt, retains heat perfectly, allows air to pass through without problems and feels good on the skin.

What it is?

Cloth is a dense fabric based on wool or semi-wool. Its specificity lies in the fact that the woolen fibers on the surface are so tightly intertwined with each other that they completely hide the free interstitial space.

This happens due to the fact that the threads, covered with teeth and scales, have the ability to connect with neighboring fibers.

Subsequently, the raw cloth is felted, as a result of which it shrinks almost by half and acquires a greater density. The description of the woolen fabric says that the highest quality cuts are obtained from fluffy merino wool, the fiber size of which reaches 7-8 centimeters. To create cheaper samples, camel or sheep fleece is used, supplemented with artificial, viscose and cotton fibers. In this case, the weft is formed from wool and viscose, and the rest of the materials become the base.

Getting the felt begins with the preparation of the sheared wool: the fleece is combed out, cleared of lumps of dirt and traces of oily sweat, and also freed from thistle thorns. After processing on a beater and carding apparatus, you can proceed to spinning on a unit intended for this. The resulting intermediate version has to be warped, that is, to create a base of threads of equal thickness and tension.

On a loom, the fabric itself is already made with a plain or twill weave. In the future, the canvas is compacted by felting. In the final stages, the cloth is washed, dyed, fluffed and brushed. The goods appear in the store, being pressed and packed.

Quality cloth looks like a fleecy matte material with a slightly rough, uniform surface. It can be painted in any shades.

Woven fabric has many benefits. So, it is extremely easy to work with the canvas: it does not slip, does not crumble or warp during cutting. The finished product turns out to be very strong, capable of serving for many years. The hygienic material demonstrates good protection from cold, is breathable and does not irritate human skin.

The disadvantages of cloth include its significant weight and high cost. It is also noted that woolen clothes are quickly wrinkled, and in places of active friction they become covered with pellets and scuffs.

Origin story

Cloth has an ancient history, because devices for creating such a material were designed many centuries ago. Such canvases were woven in Ancient Greece and Rome, and in the Middle Ages, fabric already played a significant role in European countries. England, France, Flanders and Saxony were engaged in its export.

The production of cloth was also carried out in Kievan Rus under Prince Vladimir: then this dense and rough matter became a real salvation from frosty winters, plus it was also sold to foreign merchants. Under Peter I, the opened textile factories were engaged in the production of inexpensive material for supplying the army.

Over time, the fabric became more and more high-quality and valuable, and not only the poor, but also the highest nobility began to use it.

Views

It is customary to classify woolen fabric according to several parameters.

By density

Woolen fabric can be thin, semi-coarse and coarse. The first options are characterized by the presence of a carefully dumped pile layer. A semi-coarse fabric lasts much longer due to its average density. Finally, rough - the thickest and most reliable cloth, which is of high quality, but also costs much more. When creating it, thick yarn is used.

The relative density of the threads on the warp is from 45% to 70%, and on the weft it does not go beyond 75-80%. On average, the density of the material reaches 320-450 grams per square meter, but for workwear this figure rises to 555 g / m2 and even up to 873 g / m2. The latter samples are additionally impregnated with a special compound that increases their heat resistance.

It should also be mentioned that plain-colored and melange cloth are distinguished by the type of dyeing. The first has a single shade, while the second is multicolored.

The material can be created from pure fine wool or from a mixture of different fibers. The wool content in the second variation ranges from 60 to 80%. Sometimes woolen fabric is made on the basis of cotton fibers. There are also lint-free and brushed types of canvases.

By area of use

Separately, it is customary to single out army cloth, which is made according to a strictly fixed technology. It contains only natural wool without impurities. Thanks to this, the products retain the heat generated by the body better, and also have an increased density. Such a woolen dyed fabric with fibers of different lengths is intended for sewing military service clothes, hunting equipment and warm winter clothes.

By the way, the most expensive variation of cloth called "castor" is used to create a general's dress uniform. It is always painted gray and complemented by a satin finish. Materials intended for soldiers and officers differ in the state of the rune used and the method of processing. Loose army cloth is suitable for sewing summer uniforms, and thick and weighty for winter uniforms.Appliance cloth is intended for stripes and chevrons.

It is the greatcoat variety that is used not only to provide the military personnel, but also for workers and hunters. The former receive hand protection and overalls that do not deteriorate due to sparks or high temperatures. Clothing for the second does not emit any sounds when moving, which allows you to sneak up on any animal.

She is also not afraid of sparks and retains a light sheep scent that attracts the beast.

Everyday cloth can have a different composition. It is available in numerous colors and the softness of the pile varies depending on the application. This type of material is used for the production of various kinds of clothing. It can be produced using different technologies, but it is always characterized by the presence of ironed pile and a pleasant-to-touch surface. There is also a drying cloth, which is designed to absorb moisture in the papermaking process, and a filter cloth, which provides air purification in special installations.

Various variations of the material are used for sewing hats and coats, creating costumes and workwear, upholstery of billiard and poker tables. Some experts distinguish urban cloth, which is created using a simplified technology when compared with army cloth. Soft woolen fabric has a lower density and is dyed in all sorts of shades. Urban cloth includes drape, grandfathers, drape-velor, bieber and vigogne. A separate type is sermyaga - the canvas is rough and unpainted.

The upholstery for billiard and poker tables is specially treated. The cut-off is first immersed in a special solution that makes the material softer. Then, during the drying of the felt, the villi are laid out in the same direction to ensure a smooth surface. Since such a canvas gains increased strength, it is also sometimes chosen for furniture repair. Woolen cloth with a nap is suitable for making shoes, and soft variations for blankets for government agencies.

When choosing a material for sewing a warm suit, you should focus on soft melange fabric. These samples are pleasant to the touch and do not contain coarse fibers. For expensive clothes that should last for many years, the option containing merino wool is more suitable. When creating outerwear, it is customary to choose lightweight cloth.

When choosing a billiard material, preference is usually given to elastic specimens containing nylon. It is important for the poker table that the percentage of nylon does not exceed the percentage of wool: the cards should slide, not roll onto the floor. Workwear requires the use of materials that contain polyester yarn, which improves their performance.

Care

It is not recommended to wash the cloth by hand, as such processing can damage the material. After hand washing, the fabric loses its presentable appearance, becoming covered with spools and falling off. It would be much more correct to give the woolen products to the dry cleaner for processing. However, at home, you can try to wash the item in an automatic typewriter.

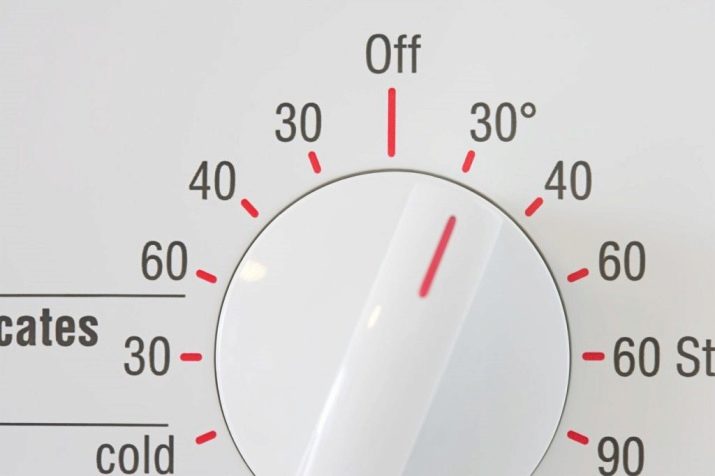

It is important that the cloth cut without "neighbors" from another material is erased at a temperature of 30-40 degrees.

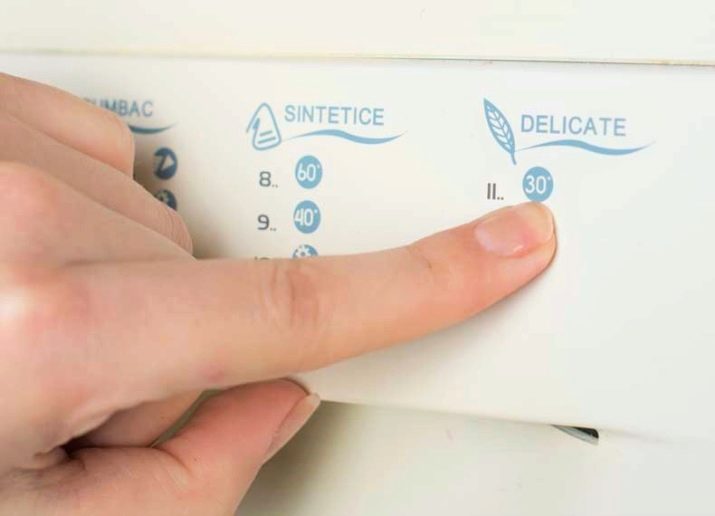

The processing time is no more than 1 hour, and the program is set to "Delicate". Use only mild liquid detergents intended for cleaning wool on the material. Bleach for cloth is absolutely not suitable. A 10-minute spin at low speed is allowed for the material.

You will often have to iron such a fabric, as it wrinkles quickly. Heat treatment conditions are usually indicated on the label, however thin varieties are usually ironed at low to medium temperatures, and thick ones at high temperatures. On average, you should focus on a temperature of 130 degrees and do not forget about steaming.

Since natural fibers are often a target for pests, it makes sense to additionally protect products from moths by treating them with appropriate means. It is customary to store woolen clothes in covers located away from moisture and direct sunlight.

To remove stains, it is allowed to use special means, but only with the condition of preliminary testing in a small and inconspicuous area. Cloth cuffs, collars and valves will need to be regularly cleaned from pills with a special device.