Beading machines

Weaving from beads is one of the most ancient types of needlework, which has passed through the centuries almost unchanged. Small beads of different colors in skillful hands fold into beautiful patterns that can be used to decorate clothes, make accessories. If for the manufacture of simple baubles and bracelets you can get by with the simplest tools (a needle and a thread), then in order to embody more complex masterpieces, you will have to attend to the purchase of a beading machine. This expands creativity.

Peculiarities

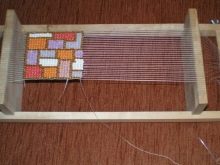

A dense beaded fabric, when the beads are located exactly one under the other, looks more professional and allows you to make fairly large items. At the same time, even a beginner can cope with the manufacture.

The main advantages of machine weaving over manual weaving include:

-

faster weaving of beaded fabric;

-

manufacturing of one-piece products (handbags, cases, casket braiding);

-

the ability to use patterns for cross stitching.

There are also disadvantages of using a weaving machine. First of all, these are the requirements for the quality of beads. All beads must be flawlessly even and the same, otherwise the harmony of the pattern and the evenness of the canvas may be disturbed.

It is impossible to make products with bends on a beading machine - Easter eggs, balls, braided pens and more.

Views

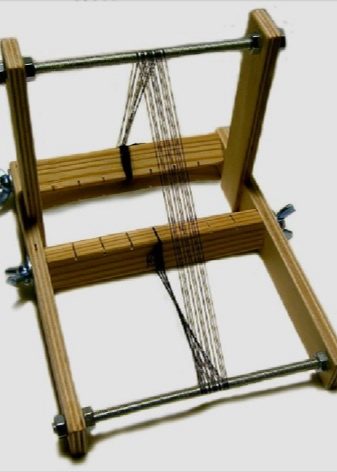

The basis of any machine for beading is a rectangular frame with working threads stretched over it. Small vertical pins are placed on the frame, the distance between which depends on the size of the used beads (0.5-1 mm). They are needed to separate the threads from each other.In industrial machines, a special spring plays the role of a separator; in homemade machines, small carnations are often used. As a basis for the canvas, a special fishing line or elastic band can be used (most often used to make bracelets, chokers).

Special designs for any size can be purchased at handicraft stores. They can be both simple and with various options (the ability to change the slope, tension force).

Depending on the material of the frame, the machines are divided into:

-

cardboard (homemade);

-

wire;

-

wooden;

-

metal.

Homemade cardboard machines are good for making 1-2 small items. Their main advantage is the price. Such a machine can be built quickly from what is currently at hand. Most often, a square or rectangular box is used for its manufacture, on the walls of which shallow (up to 0.5-1 cm) cuts are made to secure the base.

The wire beading machine is convenient due to its low price and small size, which allows you to work in any convenient place. Ideal for children. It can be used to make things of any length, the width is limited by the dimensions of the machine (about 35 rows)... The main disadvantage of this option is the impossibility of regulating the inclination of the working surface (eyes and hands quickly get tired when working in uncomfortable conditions), fragility (they break rather quickly).

Can be used to make small jewelry (bracelets, pendants, belts).

Wooden models are the most common due to many advantages. Wood is a fairly strong material that does not deform when pulled on the base of a large number of working threads. Large professional machines allow you to create canvases from more than 350 threads. And also they allow you to work with products of any length and width. In most models, it is possible to control the regulation of the thread tension using built-in spools. The angle of inclination of the working surface in most wooden machines is 45 degrees, in more advanced models this angle can be adjusted in a wide range for more comfortable work.

The metal frame is typical for professional beading machines. They are more robust and durable... But their high cost and heavy weight make them not very convenient for home use.

How to choose?

Many needlewomen recommend before buying a machine to try to work on different options, to make a small machine with your own hands from a cardboard or plastic box. This will help you understand which specific parameters are the most basic. And is such a technique really necessary? Still, a beading machine is a separate type of needlework that requires special skills and abilities.

Consider the most important parameters for choosing a machine for weaving with beads.

- The width of the work area. Of course, this factor is not very important in the manufacture of small, narrow products - baubles, bracelets, belts. But if the machine is purchased to create paintings or canvases, then the maximum width of the machine can be a determining factor.

- Maximum product length. For many craftswomen, a very important parameter.

Therefore, you should check with the seller for the maximum length of the item that can be made on the machine. Some machines have a limitation on the maximum blade length.

- Possibility to adjust the angle of inclination of the working blade. Most inexpensive machines do not have this feature. In this case, it should be remembered that for human vision, the optimal angle of inclination of the working surface is 45 degrees.

- Presence of tension adjustment of the warp thread. At the beginning of work, it needs a strong tension, which, as the canvas fills, can be relaxed for ease of work.

- Availability of additional components... The material from which the machine frame is made is not so important as the presence of additional springs, wire. This will eliminate the need for an urgent search for an unexpectedly out of order small part.

- For a novice craftsman, the optimal choice will be a small wooden machine with an inclined position of the working blade. This will allow you to make products of different sizes. At the same time, the design will not take up much space and will not breach the needlewoman's budget.

How to use?

First of all, it is important to ensure the comfort of the workplace. Having the right lighting is very important when working with small objects, as this kind of work puts a lot of stress on the eyesight.

It requires two needles to work. One long (at least 5.5 cm) for weaving and another smaller one for closing the threads. The size (diameter) of the needle depends on the number of the beads (the width of the hole in the bead).

First of all, on the machine, it is necessary to ensure the correct tension of the threads.... For this, threads of increased strength are selected, which are pulled from the right side of the machine to the left or vice versa. The instructions for the machine necessarily tell you how to thread the warp threads onto it. All of them should be tensioned with the same force, there should be no overtightened or sagging sections. The length of the threads is the length of the planned product plus 40-50 cm for easy attachment to the machine. The number of strands should be equal to the number of beads in one row plus one more strand. Each row of beads must be secured carefully to avoid shifting the pattern.

Strong thread fastening is required after work... To remove the finished fabric from the machine, all the warp threads should be tightly pulled to the weaving. The tightness of the threads ensures that the beads will not fall apart during use.