All about leather for needlework

A craftsman deciding to start producing leather goods must be well versed in the material used. It is necessary to take into account not only the specifics of its individual varieties, but also how the entire work process is organized.

Description

The main requirements for leather for needlework are its aesthetics and the presence of a unique pattern. The material should be easy to process, have high wear resistance, and then, when it comes to clothes or shoes, be comfortable to wear. Raw materials of animal origin undergo a long preparation process before being sent to the market. First, the skin is fresh and cleaned, after which tanning is carried out - treatment with substances that give the material strength, elasticity and durability. Further, the workpiece can be painted, waxed or varnished. Artificial leather (the usual leatherette or the now popular eco-leather) does not require such treatment.

Species overview

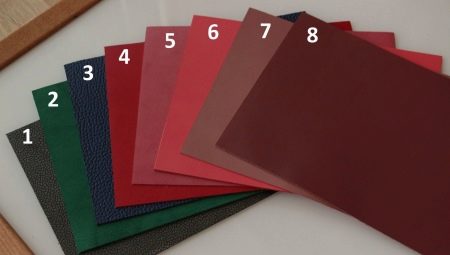

For needlework, it is customary to purchase separate pieces of canvases, cut off from a common roll, or a set of several colored shreds. Besides, blank for a variety of crafts can have a natural shade or be dyed.

By origin

All genuine leather is created from the skins of a number of animals. These can be cattle, that is, cows, bulls and even buffaloes. This material is highly durable, but it stretches well. The resulting skin can have both different thicknesses and a unique, non-repeating color. This variation is ideal for sewing clothes and creating accessories, as well as upholstery.In addition, the material can be used for embossing and burnout techniques.

Also, natural raw materials are obtained from the skins of sheep and goats - a rather thin, stretching and very tactilely pleasant variety. Such material can be used when creating clothes, accessories and certain parts of shoes. The third variety, horse skin, in needlework it is used quite rarely, but in industrial production it is sometimes still chosen to receive shoes and handbags. Not the most common material. However, it is robust, tactile and impressively thick.

Genuine leather obtained from the skin of a pig does not possess outstanding characteristics. Quite a budget material is characterized by rigidity, a large number of pores and unsatisfactory quality. Often, tearing material is used only for linings, insoles and other details that are not in a conspicuous place.

Deer hide is a suitable raw material for making suede. A durable and elastic fabric has good thermal protection, and therefore is often chosen to obtain various kinds of clothing items.

Finally, exotic options should also be mentioned: the skin of reptiles, reptiles, ostriches and even fish. Despite the fact that they always look extremely impressive and are characterized by a long service life, the high cost of raw materials usually scares off most needlewomen.

As for artificial leather, due to its lower cost, it much more often becomes a raw material for creativity. Leatherette is a polymer that mimics natural leather in color, thickness, and texture. It is a smooth material that is very easy to work with. Sometimes it even smells like its animal counterpart. For creativity, it is customary to use all types of artificial leather: leatherette based on polymer-coated fibers, durable PVC leather and eco-leather - a canvas of two layers, the bottom of which is either cotton fabric or synthetics.

By type of tanning

Vegetable tanned leather is most suitable for handicrafts, especially those related to embossing and burning. Its processing is carried out at the expense of natural tannins - that is, substances with tanning and binding properties that are present in the wood, fruits and bark of some trees. Organic acids can also be used. Vegetable tanning allows you to leave the natural color of the raw material.

In addition, there are such types of tanning as fat and chemical. In the first case, the active substance is the fats of underwater inhabitants, and in the second, solutions of chromium salts.

Nuances of choice

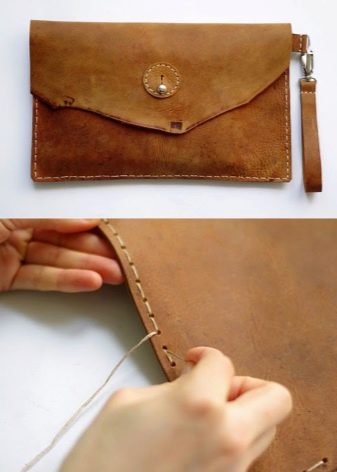

When choosing a material for creativity, you must always take into account what thickness of the canvas is suitable for a particular product. A thick flap is not always the best option: for example, for an elegant handbag it would be more correct to take soft and thin leather. Raw materials should be easy to work with, so elastic specimens should always be preferred.

Again, it is important to consider which option is better embossed, which can be waxed, and which does not require additional processing. When buying, the master should not forget about what the purpose of his creation will be, whether he will need finishing or decor, in what conditions the operation will be carried out.

A thick and dense saddlecloth, obtained from the skins of cattle, perfectly holds its shape, and therefore it is recommended for creating bracelets, belts, cases and scabbards. Crust has similar characteristics. Soft leather jacket, the thickness of which does not exceed 2 millimeters, is available in various shades. Since it is easy to sew, the material can be used to create garments.Loose suede with a short pile is pleasant to the touch and easy to process, and therefore can be used to obtain different products.

By the way, quite often the leather plates on the market are immediately sorted by purpose, which greatly simplifies the selection process.

Features of working with leather

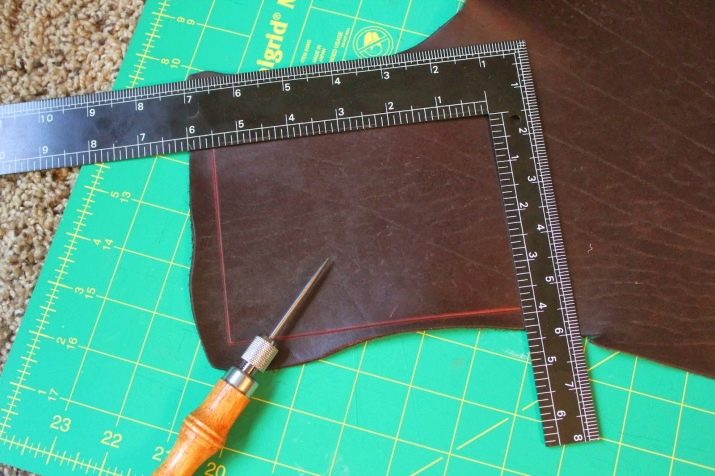

To work successfully with leather, especially when it comes to natural material, it will be necessary to prepare the appropriate tools. Standard scissors can be used to cut the canvases, but only a special knife can cope with rough dressing., the tip of which is sharpened at an angle of 30 degrees in relation to the long side of the tool.

An alternative to it can be a construction cutter. Sewing natural material by hand will turn out to be an appropriate type of sewing machine, but for more serious work you will have to start a special sewing machine. For complex elements, it is better to prepare special triangular needles. Work should always be done with a thimble.

It is better to take threads that are not very thick, strong, but by no means cotton. Leather products are quite often exposed to precipitation, and cotton fibers are destroyed precisely by moisture. The best solution would be to choose a nylon thread. It will be most convenient to apply the markings on the skin with a gel pencil, and the elements are measured with a bright and sometimes transparent ruler. Since the seam allowances are always glued, it will be necessary to prepare a special tape, sticky on both sides, or a rubber type of fastening substance.

All about leather for needlework will be described in the video below.