How to Choose Tailor's Pins?

The sewing process is very difficult but interesting. To learn how to sew, you need to grasp the basics of cutting, work on different devices, and be able to use all the auxiliary equipment. One of the most demanded products that all seamstresses work with are pins. With this little detail, a significant result can be achieved.

To use pins correctly, you need to navigate in their variety.

Why do we need it?

The appearance of pins was caused by the desire of tailors to sew clothes for a particular person. It was inconvenient to use needles to pinch fabric in certain places, so tailors needed new products that would simplify the process. For the first time, a semblance of a modern pin was made in the 15th century, but the resulting object was used for decorative purposes or for binding papers.

Products, which began to be created especially for tailors, appeared only in the 18th century in France. The number of such goods was small, but gradually increased.

With the advent of pins, tailoring became easier, and seamstresses could produce more garments per unit of time.

Tailor's pins are as simple as possible. It is a metal rod, sharp as a needle and having a round or ball at the other end that prevents the pin from flying off the fabric. Using this product, you can:

- ensure chipping of two halves of the fabric, eliminating the procedure for sweeping with threads;

- make folds on clothes and distribute the fabric evenly over the entire surface;

- grab the material where necessary, ensuring easy sewing of any things;

- immobilize several layers of fabric that are superimposed on each other and may move during the sewing process, which will disrupt the appearance of the finished garment;

- pin a zipper, preparing it for sewing on a typewriter;

- fix the details of the garment during the packaging process.

Thanks to a small metal needle with a stop at the other end, seamstresses can quickly and conveniently cut, sew and pack clothes.

How do they differ from each other?

Due to the special relevance of tailor's pins, manufacturers began to create different versions of this product. Due to the wide variety of fabrics, it was necessary to come up with different types of pins that would not spoil the material and allow seamstresses to work comfortably.

Sewing pins may differ in material. Initially, they were made from copper, while modern versions are made from brass and nickel-plated steel. Steel is most often used, as it is a more comfortable material that does not rust or dull for a long time. The difference in composition also affected the color of the products, for example, copper needles with a stop could be red or dyed additionally. The steel varieties are all metallic in color.

Another important difference between pins is their thickness. For different fabrics, it is worth using products of different diameters. If a thick needle with a stopper is inserted into a thin fabric, the fibers will disperse, and holes will be visible on the finished garment. When working with very thick and dense fabrics, it is difficult to pierce them with a thin needle: it often bends, which prevents the desired result from being achieved.

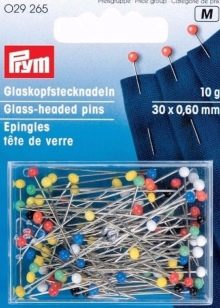

Taking advantage of the experience of predecessors, seamstresses use the thinnest needles with a stop for silk, synthetics and other delicate fabrics. Their thickness is 0.5 mm. For normal weight fabrics, pins with a thickness of 0.6 mm can be used. These needles are sharp and easily pass through any matter. If you need to work with thick fabric, it is better to choose pins with a thickness of 0.8 mm. They will not bend and will provide a secure fit.

In addition to thickness, pins can also vary in length. If a seamstress connects parts to each other, then it is more convenient to use sufficiently long products - from 3 to 4 cm.If there is a need to temporarily fix something, then small varieties up to 3 cm will be more convenient. If you need to chop off a thick fabric for work, then you cannot do without long needles (4-5 cm).

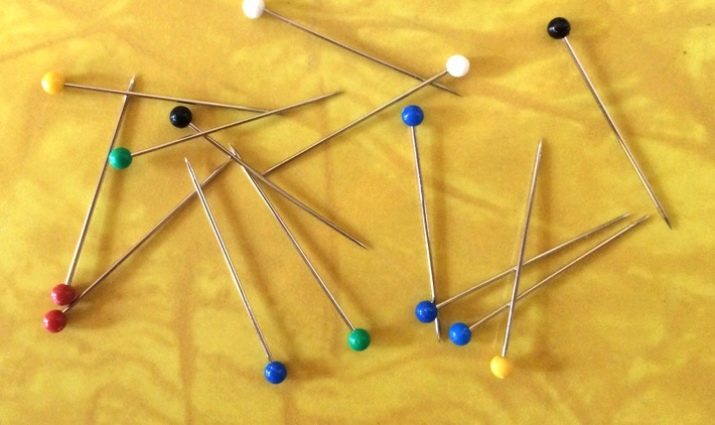

The most visible difference between the pins is the shape of their stop. You can find such varieties:

- carnation (model with a flat small plate, similar to the head of a real nail);

- a needle with an eyelet, where the end of the product is twisted, forming an eyelet;

- metal ball (soldered piece of metal);

- a plastic ball, which can be medium to fairly large (usually painted in different colors);

- a flat plastic figure - a limiter of any shape that does not allow the needle to slip through the fabric;

- T-shaped (needed for working with thick fabrics).

The presence of a wide variety of pins allows you to choose the right option for a specific type of work.

Varieties by purpose and type of material

Due to the fact that there is a fairly wide variety of fabrics that differ in thickness, presence or absence of stretch, fiber characteristics, it is necessary to choose the right pins so as not to spoil the finished product. There are the following types of fixtures.

- Universal. They are 3 cm long and 0.5 mm thick. Manufacturing material - steel. You can use these varieties for stretch fabrics and most materials. Do not use them on silk, as puncture holes may remain on it (the needle is not sharp enough). It is inconvenient to use them for thick fabrics, because the length of 3 cm will not be enough to securely fasten the parts.

- For silk. Made of thin steel, 0.5mm thick and very sharp tip.Unlike versatile products with an eyelet, this option has a small flat head. Carnations are easy to work with, as they do not cling to the threads and do not pull out. The length can be different: on sale you can find both small options for 2.5 cm, and standard ones for 3 and 3.2 cm.

- With a rounded end. Used for knitwear. These needles do not pierce the fibers, but move them apart and pass through the fabric without violating its integrity, which allows the fabric to return to its original appearance after removing the pin. On sale there are small options with a length of 2.5 cm and standard 3 cm.

- For quilting. Suitable for sewing thick and warm fabrics. These are long products of 4-4.5 cm, thin and sharp, which makes it easy to pierce material of any density and thickness. They can be metal or plastic balls as restraints, but flat-headed needles are most often used.

- For folds. Convenient for creating folds on fabric, used for thin and medium-thick fabrics. The length can be 2.5-3 cm, the thickness is 0.5 mm. The needles can be with plastic colored or metal beads at the end.

- T-shaped. A completely metal product with an edge curved perpendicular to the base. These pins are used to work with denim and overcoat fabric. The length can be 3.2 or 4.5 cm and the thickness is 1 mm.

Safety pins are used to pull elastic bands, cords and braids into tight pieces of clothing, they are comfortable and practical... Thanks to the metal body, they do not break and do their job well. There are small, medium, large and very large decorative varieties of these pins.

To buy a set of pins for sewing, it is important to know the basic parameters of these products, as well as the material from which the clothes will be cut and sewn. To purchase a quality product, you can look at customer reviews about a particular company, consider the advantages and disadvantages of each option and find the most optimal one.

Selection Tips

When planning to work with fabrics, cutting and sewing any product, it is worth purchasing pins, which will greatly facilitate the process and speed up the achievement of the desired goal.

To find the best option for a given product, you should choose it based on the following nuances.

- Type of fabric. If the sewing is made of delicate material, then it is worth taking only pins for silk. These are fine needles that will not leave marks on the finished product.

- The length and thickness of the pins. For beginners, it is best to take a universal variety, the thickness of which is 0.5-0.6 mm, and the length is 3-4 cm. Such a set consists of 1000 pieces, it will allow you to do only with this purchase for a long time.

- Limiter shape. This nuance is important for a certain type of work. If the pins are needed for fastening parts, fixing or creating folds, then you can buy options with a volumetric ball. For those cases when the seamstress will cut using pins and sew with them, it is better to take products with a flat stopper. Products with an eyelet or carnations can be considered universal: they are convenient for most types of work.

- Tip sharpness. This is a very important nuance for knitted fabrics that do not respond well to piercing with sharp-edged needles. For knitwear, you need pins with a rounded tip. Needles for silk and thick fabrics should have a very sharp edge so that you can easily thread the needle without damaging the fabric or leaving an unnecessary mark on it.

- Firm. Having the opportunity to buy quality goods from a well-known sewing brand, it is better to give preference to just such products. Thanks to customer reviews on manufacturers' websites, you can choose the best type of product for specific work.

The cost of pins can be different: it depends on the quality, thickness and length of the metal, on the type of stopper, on the number of pieces in the package and on the brand that produces these products.

Before buying any product, you should compare it with a similar one, so as not to overpay for the brand, while receiving products of average quality.