All about vacuum packaging

Packaging plays an important role in the storage and transportation of various products. It is offered in several versions, and vacuum is in high demand for a number of reasons. As a material, corrugated film, bags can be used, each with its own characteristics and advantages.

When vacuum packing, it is necessary to follow the rules in order to preserve the properties of the contents.

What it is?

The material for vacuum packaging can be films, bags or bags in which the product can be placed. The principle of operation is as follows: the air from the inside can be pumped out both with special equipment and at home without it.... Once the process is complete, the edge of the film is sealed and the seam is sealed.

The main task of packaging is to keep oxygen out of the food. This will prevent the process of fermentation, rotting and drying out, bacteria will not be able to develop in such an environment.

The product is protected from moisture, which allows you to maintain a presentable appearance, aroma and freshness. Even if the product needs to be stored in conditions with low temperatures, but for some reason this is not possible, thanks to vacuum packaging, you will not have to worry about the quality of the contents.

The freshness of products in such material lasts longer., therefore, you can often see dried fruits, vegetables, spices, semi-finished products and even dairy products in vacuum packaging. Of course, this is not a lifesaver, but this option is suitable for storage for a certain period.

Advantages and disadvantages

The main advantages of operation include a long period of preserving the freshness of products, which is provided in this way.And also moisture, dirt, ultraviolet rays, dust do not get inside, because they are destructive for food products.

For ripening vegetables, a vacuum is best suited, the beneficial properties are preserved.

With the help of packaging, you can store food in portions by spreading it in a cut form. You can save space in your suitcase when transporting things in a vacuum bag.

But it should be noted that there are disadvantages. Packaging cannot completely protect against mechanical damage, therefore additional materials are often used if a long-term transportation is planned. The shelf life is limited and when it comes out the vacuum will not retain the taste and freshness of the contentsif it is food. In such conditions, anaerobic bacteria can survive, and they are causative agents of botulism.

But if you do not violate the rules of packaging and transportation, you can not worry about the shortcomings.

It is imperative to use only durable and reliable materials that meet quality standards.

Materials (edit)

Soft materials are used for vacuum packaging under normal conditions, so there is no need to operate special equipment. Films and bags are most often suitable for food products, they are inexpensive, and you can do the packing procedure yourself.

Among the types of such products can be called a soft film for the evacuator, which is produced in rolls. Rigid packaging is sold in the form of cans, plastic boxes and boxes.

It is necessary to choose a product taking into account what will be stored inside. If we are talking about liquid or bulk products, it should be blown film. Gas-filled materials are suitable for high loads. But the combined film is used together with substrates and is often found on store shelves.

Vacuum films are available in the upper, lower and Flow-pack types. The first option is suitable for sealing the packaging, and the second for molding. Available in rolls of various widths, lengths and film thicknesses. These indicators characterize the density and tear resistance.

Polyamide and polyethylene used for the production of vacuum bags. It shrinks as the air is pumped out, taking the form of the product inside. This option is perfect for home use, as it is versatile and practical.

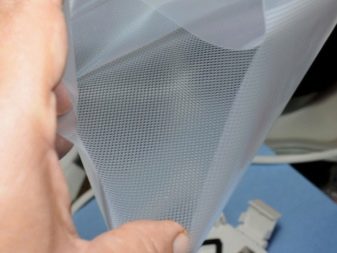

Corrugated vacuum packaging used in enterprises where there are special machines. It is a multi-layer material that consists of polyethylene and polyamide alternating with each other. Thanks to this surface, the machine can completely evacuate the air from the package. Such bags are also called embossed or corrugated.

Applications

Vacuum bags and sacks are in great demand in the food industry. They store and transport meat and fish products, semi-finished products, fruits, berries, nuts, cereals, tea, spices and even ready-made meals. Some metal, plastic and wood products can also be packaged in this manner.

It should be noted that at home a vacuum is suitable for compact storage of clothes in a closet or for transportation in suitcases.

The fabric will be protected from pests, dust, moisture and all kinds of dirt. Thus, we can say with confidence that this type of packaging is practical and convenient for storing a variety of things.

If you want to be able to vacuum at home, you can purchase a packer.

There are many models of such equipment on the market from different brands. When choosing, you need to pay attention to the conditions under which it will be applied.

Mechanical pumps for packers do not need a network, so there is no better option for hiking. The main characteristic of the equipment is the power of the pump that evacuates the air. And the higher it is, the better the performance of the device.

For industrial enterprises, it is better to choose professional equipment, and for household use, you can consider simpler models.

It is important to consider the volume of the package, that is, the batch of food or other items.

How to use?

If you need to put things in a vacuum package, you should prepare them for this.

It is important to make sure that the items are dry and clean as this can affect the odor when opened.

Clothes and shoes must be sorted by season, size and other characteristics. In addition, it will help to select the parameters of the vacuum package. Things are sent to the bag, distributed around the entire perimeter. After that, the package is closed and the sealing is carried out.

Most clothing packages have a flap lid. The air can be pumped out with a conventional vacuum cleaner at low power. When the package is flat and firm, the flap can be closed and the package can be sent to the shelf in the closet or folded into a suitcase for a trip.

There is compression bags that do not have a valve and therefore air is released by twisting the package... Then it is enough to close the lock tightly, and things will be hermetically stored. It is extremely important to check the accessories before this, if possible, hide it inside the clothes so that it does not damage the packaging.

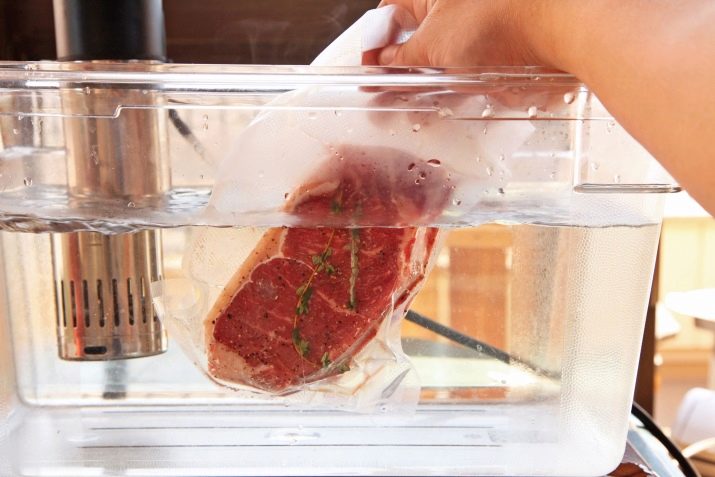

If it is necessary to pack food products, there is no evacuator, you can extract air from the package at home... Vegetables must be washed and dried or peeled, the meat must be separated from the bones, that is, all unnecessary must be removed. The food is folded into a ziplock bag, which must not be closed completely, leaving a small hole. Then place the package in a container with water, it squeezes out the air completely, after which you can close the fastener.

As you can see, everything can be done without any extraneous devices.

Vacuum packaging in sacks and bags can be reused... It is a useful tool that every home should have if it is necessary to preserve food, save space in the freezer, closet or suitcase, depending on the contents.

The shelf life of the film depends on what is in it. It is also important to consider the conditions and temperature of the place.

Meat cannot be stored for more than 10 days, but cheese can remain fresh for two and a half months... Bulk products can be packaged for several months.

As for clothes, it is much easier with them, but you need to take things out every few weeks and ventilate them in the fresh air, after which you can pack them back.

The following video provides an overview of the BANGGOOD vacuum sealer for home use.