Hydraulic brakes on a bicycle: device, pros and cons, brands, choices

Modern bicycles (cycle bikes) can be equipped with a variety of braking systems. Each of them has its own pros and cons.

Among the available varieties, hydraulic brakes have become quite popular in recent years.

Cycle bikes with hydraulic brakes are in vogue today and enjoy consumer interest among fans of fast driving.

Device and principle of operation

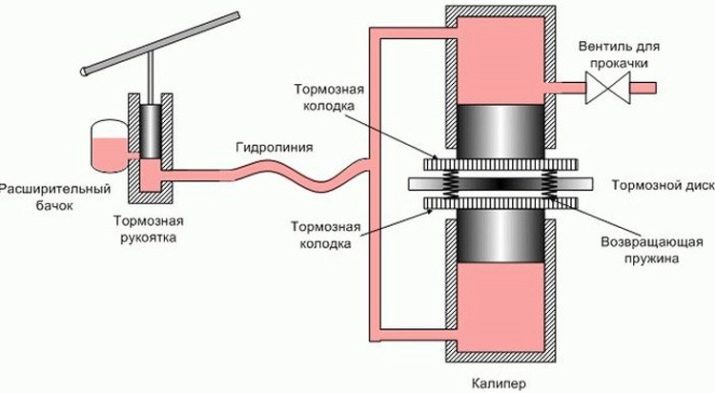

The task of any braking mechanism is to stop the vehicle. Basic components of hydraulic brakes:

- hydraulic line (hydraulic line);

- brake disc (rotor);

- brake machine (caliper);

- brake handle.

Due to this structure, the system does not require frequent adjustments, and it can be in operation for a long time.

Let's take a look at how a hydraulic brake works. When the brake lever is squeezed, pressure builds up in the hydraulic line and pushes the brake fluid out of the main hydraulic piston. After that, it enters the slave cylinder. Under the force of pressure, the brake pads are brought together by means of pistons, and their friction against the rotating rotor leads to instant wheel blocking.

Advantages and disadvantages

Like other braking systems, hydraulic has its positive and negative sides. Let's start with the benefits.

- The first and indisputable advantage is that Even in the most common braking system, both brake pads press on the disc from both sides.

- Caliper self-centering, When the brakes are in excellent condition, the service has been timely and the pistons are clean.This advantage is the result of the first point. In the process of adjusting the brake when the brake lever is squeezed, the brake machine independently compresses the brake disc, and you just need to fix the caliper to the frame. It is not required to adjust the clearances between the pads.

- Excellent transmission of braking force and predictability... The hydraulic system is not dependent on dirty jackets and cables, which means that after driving through mud, the hydraulic brake works the same as before.

But there are also disadvantages.

- Brake fluid stores moisture. Regardless of what kind of brakes you practice - based on DOT or mineral oil. One way or another, moisture gradually penetrates inside, which reduces the boiling point of the brake fluid.

- The hydraulics are boiling. The lower the boiling point, the less heat energy is required for the brake fluid to boil. When a long descent awaits you, during which you have to systematically slow down, then at some point the brake fluid will overheat and boil. After the liquid boils, liquid and gas will appear in your brake system instead of a homogeneous liquid.

- Complicated service. Due to the fact that the fluid accumulates moisture, the hydraulic brakes need to be pumped. It is very difficult to do this on your own without a set of necessary tools. Knowledge and skills required. If the brake line is torn, bent, punctured, you will need to purchase a new one or return the brake system for repair.

- Price. A good hydraulic brake costs quite a lot of money.

Comparison with mechanical

The structure of mechanical and hydraulic brakes is largely the same. Nevertheless, it will not be superfluous to compare the difference on individual points. Here is a list of the key features.

- Mechanical disc brakes easier and cheaper, as a result of which they are suitable for those who choose an inexpensive brand of bike.

- Hydraulic brakes need a special workshop for the replacement of spare parts and components, pumping, repair of the hydraulic line. There is a reason to purchase them when the service center is located nearby in order to contact him for support.

- Hydraulics it is preferable to practice in particularly difficult conditions where power, precision and high-speed braking are a priority.

Manufacturers overview

As mentioned above, the disc braking system is divided into 2 main types: mechanics and hydraulics. Each of them is endowed with individual technical characteristics, pros and cons. Actually, these parameters are used to set prices. Of course, the manufacturing company also plays a significant role. Conventionally, the disc brakes price policy can be divided into 3 groups.

- The most budget-friendly are mechanical braking systems that range in price from $ 20 to $ 30. These are the following samples of popular companies: Shimano (AceraBR-M416-R), Tektro Aquila, Tektro Novela. Equipped with rotor only.

- Average prices for braking systems range from $ 30-100. These are hydraulic brakes from the following companies: Shimano, Tektro Draco, Hayes, Magura, Avid Elixir and XLC. Available with or without disc.

- The most expensive and prestigious hydraulic brakes are in the $ 100-525 range. They are produced by some of the companies listed above, as well as companies SRAM and Formula.

Views

As a rule, disc (also known as rotary) brakes are mounted on bicycle bikes, which are designed for extreme riding, even in winter. By the type of the drive, they are divided into 3 modifications.

- Mechanical disc brakes. Same as conventional rim brakes. They are equipped with a cable that is pulled up by means of a drive linkage so that the brake pads are pressed against the rotor. The mechanical device can be made in the form of a cam, a wedge or a lead screw with a multi-start thread.The wedge and cam have the same structure, only the wedge moves and the cam rotates axially. The cable pads move along parallel planes.

- Hydraulic brake. It is implemented in such a way that the control center (cylinder with piston) stands directly on the handlebars of the bike in the brake lever. It manages the shoes that are mated to each other with a durable and wear-resistant sleeve. This structure is characterized by tightness. A liquid substance passes inside it - oil. In the bulk of modifications of such brakes, there is no expansion tank, as a result of which their maintenance requires special skills and tools.

- Hybrid. Combines mechanics and hydraulics. The hydraulic side contains 2 cylinders: power and control. They are washed by some volume of oil. These cylinders are housed in the brake housing. They are influenced by a cable by means of a lever.

How to choose

When choosing and purchasing hydraulic brakes, you must first find out where you can buy spare parts for them, so that in the event of a breakdown of any component, you do not have to replace the complete set.

Hydraulics should be chosen only by those who drive through the territory with difficult conditions for movement and adore extreme sports.

In other cases, there is no need to waste money. Buy mechanical or hybrid versions that are the best solution for city travel and cycling... Their reliability and ease of use will not cause disappointment in the perfect purchase.

How to install

You will need the following components and tools:

- disk, hardware for fixing on the sleeve;

- brake machine, with it - adapter and pads, brake lever;

- cable;

- hex key;

- nippers;

- clamps for fixing the cable to the frame.

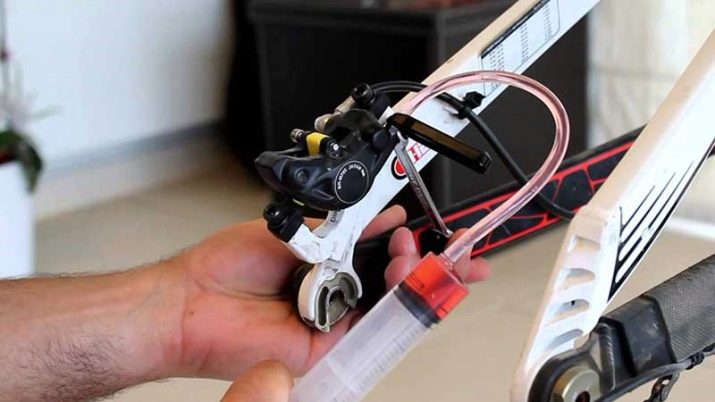

Before installing the hydraulic brake on the bike, fill it with a special fluid. Shimano products use mineral oil, other models use DOT fluid. To remove air from the hydraulic line, it needs pumping.

Tight fixation of hydraulic lines to the working and power cylinders is the main condition to prevent air from entering the system.

After a brake hose rupture, these areas are the second most likely to cause air bubbles.

Next, do a few sequential operations.

- Turn the bike over, remove the front or rear wheel (depending on the location of the brakes) and mount the disc on the hub.

- Install the brake handle, then connect the brake hose.

- Install a brake machine with an adapter on the frame, only it is not necessary to fix it thoroughly.

- Install a bicycle wheel with a disc.

- Align the hose with hose clips or guide holes. They are present in those bike modifications where hydraulics are predetermined from the very beginning.

- After connecting the hydraulic line, make sure that it is operational and reliable. To do this, gently press on the brake lever of the bike. If everything is done correctly, the pads compress the rotor equally. Pressing the pads against the rotor sets the brake machine to the workplace, after which it is required to tighten the fastening screws to the end.

- If the contact of the pads with the disc is loose, or they come to it, disrupting the rhythm of movement, press the brake lever 10-20 times, holding the brake machine by hand.

Incorrect positioning of the brake machine on the hydraulics is the main cause of poor hydraulic brake response.

Unscrew the caliper if necessary, then reinstall.

After the installation is complete, the system needs to be configured. Just remember so that air does not enter the system, it is better not to turn the bike over during the tuning process.

How to choose a hydraulic brake can be found in the video.