All About Bicycle Head Columns

The steering column of a bicycle is a functional unit, without which the bicycle would go only straight, not being able to turn to the side. On such a bike you would not go far, you would go in the wrong direction and on the wrong streets. When turning, you would stop, and without steering the bike, no matter how fast it goes, it would fall on its side with you.

Steering gear

The steering column contains all the parts you need to operate the steering wheel. It includes the following elements.

- Steering tube - the cyclist holds onto it with his hands when riding. It contains accessories and gadgets.

- Steering wheel - a shortened tube, to which the steering "stick" itself is fixed by means of a bolt bracket or a retainer.

- Support pipe - part with internal fasteners, rigidly fixed to the fork. This, in turn, holds the front wheel of the bike. The turns of the steering wheel coincide with an accuracy of fractions of a degree with the turns of the fork and the front wheel in the right direction when driving.

- Head tube - a large diameter pipe, which is already part of the frame. For stable and smooth operation, the entire mechanism is "set" on cups with ball bearings.

- Bearing kits - upper and lower - do not allow the steering wheel to dangle. The conical support contacts the bottom set.

This scheme has been tested by many years of experience in the practice of manufacturers and users of bicycle products. The steering column has certain standards and diametrical dimensions that differ from one bicycle model to another.

Varieties of steering columns

There are 4 types of steering gears: threaded, threadless, integrated and semi-integrated. Each of these varieties is structured as follows.

Threaded

In this assembly, the head tube is secured with a lock nut. The thread is cut on the top cup. Advantages - light weight and low cost, has been used since the time when multi-speed bicycles did not exist. The disadvantage is that the threaded column is difficult to set up and has a reduced reliability. Low moisture resistance is to blame for the latter: as soon as the bicycle gets caught in the rain, water flows into the steering column.

In general, the design resembles a pedal or wheel hub. Over time, the threaded steering column may spontaneously unwind - check all connections from time to time.

Threadless

The structure of the threadless steering column implies a different mounting method. The top and bottom cups are clamped in the head tube itself. A ball bearing with a guide cage is placed in each of the cups. Assembly of the mechanism includes 2 stages:

- insertion of special rings and a rudder outrigger tube;

- fixing the steering tube.

Here the cups and ball bearings are removed from the head tube. The direct load from the fork-type retainer bypasses the threadless design. The threadless column is generally of the non-integrated type.

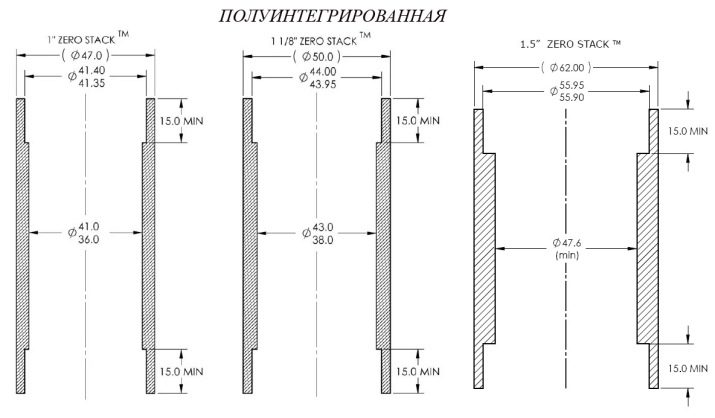

Semi-integrated

The semi-integrated mechanism differs from the non-integrated one in that the bearing crowns in it, together with the cups, are completely inserted into the head tube. Only anthers go out. The semi-integrated mechanism consists of a set of parts that allow you to easily and accurately adjust the height of the handlebar.

The entire assembly has a finished view - both in section and in general view from the side. The resulting handlebar position allows the rider to make better use of the bike's overall geometry, creating less windage when riding upwind and uphill. The fact is that the threadless design itself makes it possible to use a "recumbent" steering wheel. This effect is most fully felt by bikers with a road bike.

Integrated

This device is such that there are no cups in such a mechanism at all. The ball cage is immediately inserted into the head tube. There are no grooves along which the balls are rolled - bulk bearings (without crowns-separators) quickly grind off and will slip, rather than rolling along the inner surfaces. The integrated steering column needs the same frame adapted for the same mechanism, it is not interchangeable with other varieties.

Such a steering wheel on your own, outside the bike workshop, is more difficult to repair, and the diameters of the pipes have an impressive range of ratings.

Standards

All steering columns have standards set by leading suppliers. The goal is to promote their own ideas that have not yet conquered the market, or to protect themselves from counterfeiting by little-known Chinese firms.

- Campagnolo - semi-integrated column with a cup and ball bearing in a tapered design. The bike frame is sharpened in a special way.

- Perdido - semi-integrated version, different by 4 mm from the more widespread ZeroStack version.

- Columbus - a classic from the Aheadset company. Protected against counterfeiting and unformatted modification by a special value for the pipe diameter.

- Onepointfive Standard - non-integrated steering column for a wide diameter tube. Several manufacturers here have teamed up to produce parts for downhill and other extreme bikes.

- Foldable steering column - the prerogative of bicycle manufacturers striving to make a transformer out of a bicycle, extremely easy to transport on trains and planes, as convenient as possible to store in small rooms. These are, for example, bicycle designs from Langtu. The angle of inclination of the folding structure is from 25 degrees.

The classification by parameters is much more comprehensive. The diameter of threaded columns is as follows:

- 1 inch - the outer diameter of the cups is 30-30.8 mm, the inner diameter is 26.4-27 mm;

- 1.125 inches - 34 and 30 mm, respectively;

- 1.25 inches - 37 and 34 mm.

Simple threadless ones have the following bore diameters:

- 0.833 inches (O.D. EC-32 marker) - 32.7 and 26.4 mm for outer and inner diameters of cups, respectively;

- 1 inch (EC-30) - at 30.2 and 26.4 mm;

- 1.125 "(EC-34) - 34 and 30 mm in diameters;

- 1.25 inches (EC-37) - 37 and 33 mm;

- 1.5 inches (EC-49) - 49.7 and 39.8 mm;

- 2.21 inches (EC-56) - outside diameter 56 mm, inside not regulated.

Semi-integrated threadless columns have the following outside and inside diameters for bearing parts:

- 1.125 inches (ZC-41) - at 41.3 and 44 mm;

- 1.5 inches (ZC-49) - 49.7 and 39.8 mm;

- 2.21 "(ZC-56) - 56mm Outside Diameter;

Fully integrated threadless - have the following ranges:

- 1 inch (IS-38) - 38 and 26 mm;

- 1.125 inches - (IS-41/42/47) at 41.3, 41.8, 47 (any of the values for the outside diameter) and 30 mm (for the inside);

- 2.05 '' (IS-52) - 52mm O.D.

The parameters are indicated on the original packaging with details.

Features of selection and installation

It is advisable to choose steel cups and bearings. Non-ferrous metal (aluminum alloys), composite materials and plastic are not suitable here - they do not have sufficient hardness and strength, wear resistance. So, aluminum balls burst more often than wear out - from shock and vibration. Plastic and composite rings wear out quickly both from rolling the balls themselves and separators over them, and as a result of sliding along the pipe itself and the head tube.

If, when installing a new kit, it turned out that the groove was not formed on the cups, balls, rings or a separator, but in the head tube itself, the frame must be replaced, not the steering set. A dangling steering column will simply break new bearings for several tens of kilometers.

The steering column is adjusted immediately during assembly. Once you tighten the structure thoroughly, an incorrectly adjusted stem will not allow you to ride comfortably.

For information on the features of bicycle steering columns, see the next video.