All About Laser Burners

In recent years, various kinds of unusual hobbies have come into vogue. Many even managed to earn a lot of money from this, some made it their main occupation. One of these hobbies is pyrography, which is impossible without two main components - the basis for the drawing ("canvas") and the burner. Now mainly laser burners are used, they will be discussed in the article.

Peculiarities

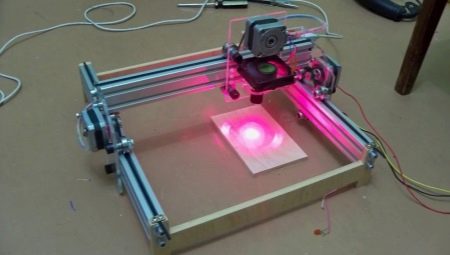

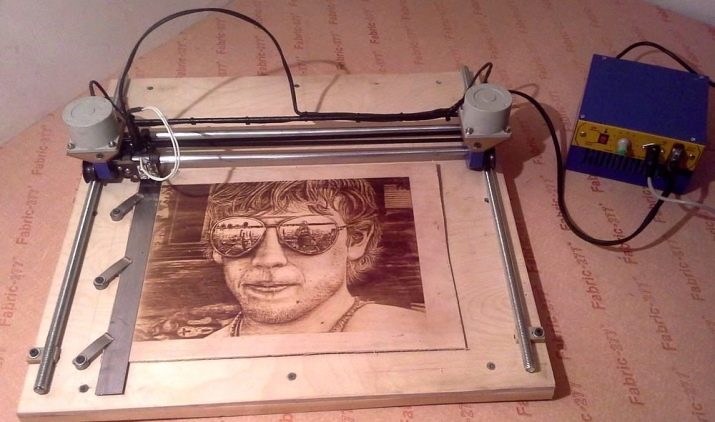

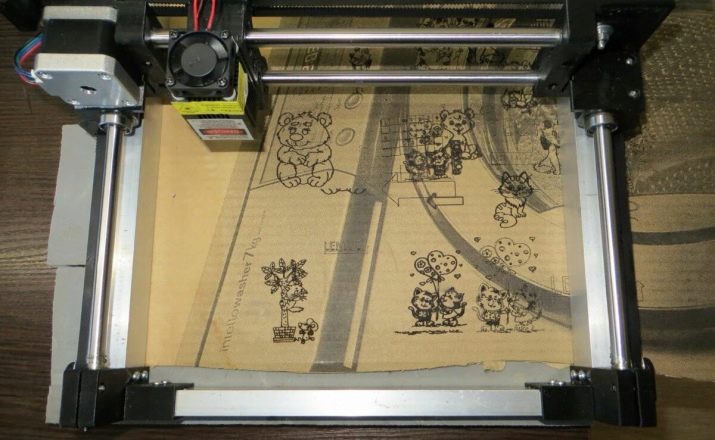

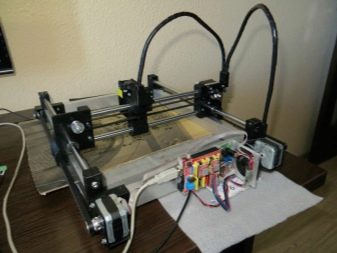

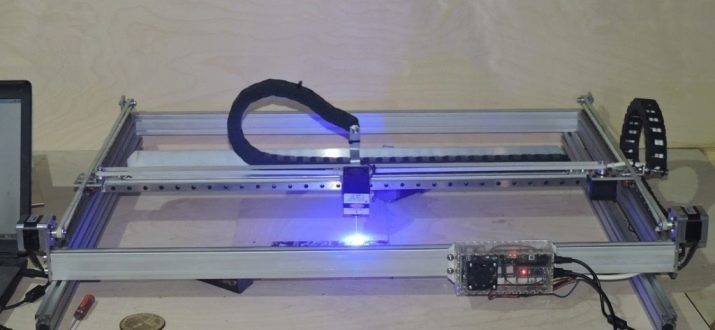

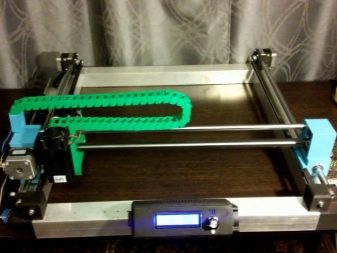

The most popular device in this category is the CNC burner. It is also called a pyrograph or pyroprinter. This is what is most often meant when a laser burner is mentioned. The unit is a device in the form of a machine tool with numerical control (CNC). With it, you can create various paintings and images by burning different materials on the surface, such as wood, leather, plywood and others. There are also manual counterparts. They are more difficult to manage.

Recommended for use only by professionals. And they also require stricter adherence to safety precautions.

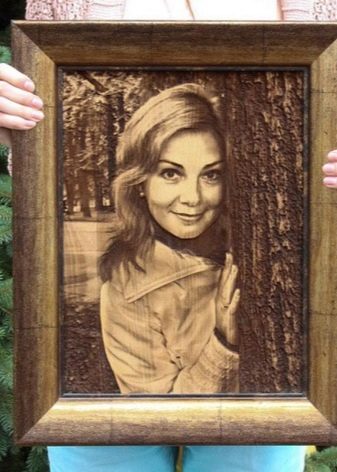

A clear advantage in favor of purchasing a device is the possibility of using not only professional artists or people with the appropriate skills, but also those who are not related to drawing, engraving. The device is configured using a computer. The laser burns the selected image on its own for a short period of time. A rational approach to business can result in very cute images, paintings (including portraits), boxes, cases, drawings on phone cases and much more.

Computer control makes it possible to create accurate images and subsequent adjustments.

Principle of operation

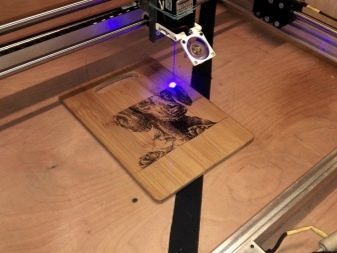

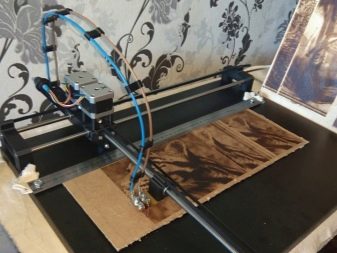

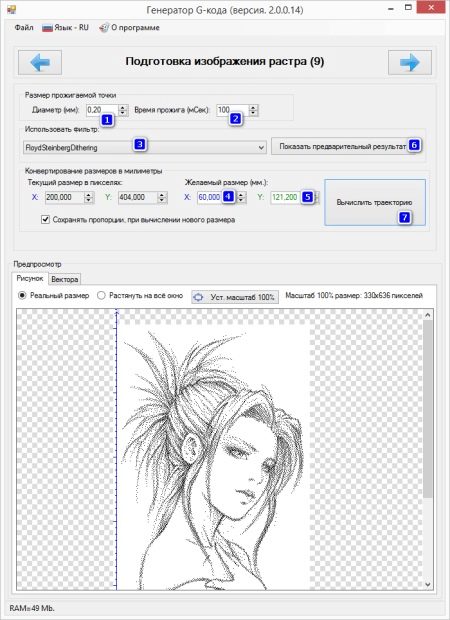

The principle of creating drawings is quite simple - as already mentioned, the surface is burned through. The CNC machine has a laser that moves. When turned on, the burner adjusts the movement and duration of the laser stay on the entire surface of the "web". The longer the laser is held in one place, the stronger the burn will be, and the darker the burned area will look. If the laser practically did not linger in some place, then it will be light or slightly darkened, and the darkest color will be black.

The laser burner works on a non-contact principle (unlike a nichrome laser). The image itself is burned out with dots. Changes in tones are possible due to a change in the density of these points in a certain area.

The image is selected and loaded into the program... Before that, it is digitized, if necessary. Further, all processing falls on the program, and the wizard only needs to prepare the material for applying the image, and start the program. When burned out, an odor is formed. In most cases, it is not too noticeable and does not require additional ventilation.

In case of sensitivity to odors, it is recommended to place the device in a non-residential area.

The principle of operation of the manual apparatus is simpler - the master himself "draws" the images.

What is required to operate the device?

You don't need a lot of tools to create pyrographic images.

-

Device... The main characteristic of laser burners is power. The larger it is, the faster the device will work. The optimal value is considered to be 20 watts. Laser burners are versatile in that they can work on different surfaces. But this does not always apply to metals. Only a number of models can burn patterns on metal surfaces. These points should be kept in mind when choosing a device.

-

Program... It is with its installation that the configuration of the device should begin. Leadership among the best CNC software belongs to Pytoprinter. It is usually installed on a computer using memory media. As a rule, the latest versions of the program are adapted for the relatively recent versions of Windows (for example, Windows 10). Nevertheless, it is better to follow the program updates yourself.

-

Material for work. It is best, obviously, to burn on wood. Preferred options are cedar, alder, beech and other precious woods. But they are too expensive. Much more budgetary and affordable plywood and MDF plates.

-

Safety glasses are required. Working with fire (laser) is not harmless to the eyes. If you are sensitive to odors, you need to purchase a protective mask. The burning smell can be especially noticeable when working on eco-leather.

Application

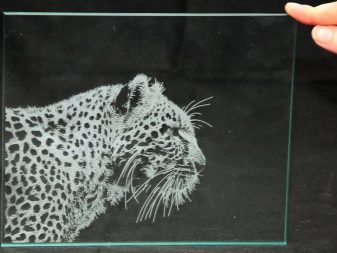

Of course, the main area of work with such laser devices is wood burning. Often, wooden or plywood plates serve as a "canvas" for paintings, inscriptions and other things. The device is used to create works on leather, cardboard, rubber, plastic products. In rare cases, burning on glass or metal is possible. Some models provide the ability to work on foam.

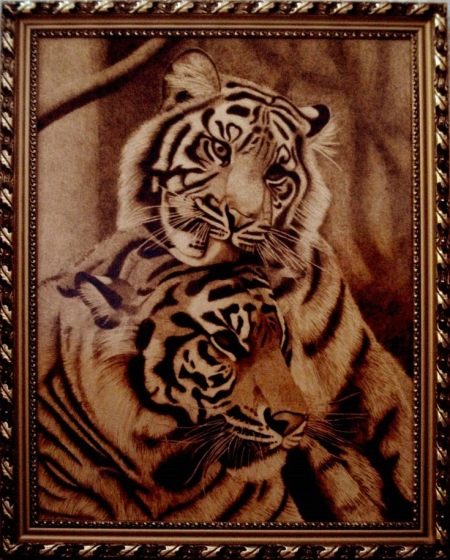

Often, items with burnt engraving include purses, bags, belts, kitchen utensils (in particular, cutting boards), advertising signs, and even business cards. Laser burners can be used on many types of fabric - felt, eco-leather, denim, cotton and others. Appliances are used in scrapbooking. A portrait burned on glass or wood is considered popular and original.

A special place is occupied by the burning of paintings on wood. In some old and not only private houses, you can find landscapes. Most of them are handmade and have been around for quite some time.However, landscapes remain popular even now and can even become a source of income for the master. The most difficult (in terms of execution technique for a CNC device) are snowy landscapes. And also the beauty of the images depends on the type of wood on which the work was performed.

It is allowed to use devices not for burning, but for cutting.