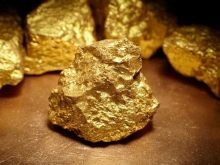

Gold mining from stone

For hundreds of years, humanity has been engulfed in a "gold rush". The precious metal of the color of the sun has been a symbol of wealth, power and power since ancient times. In the modern world, the country's large gold reserve guarantees and ensures economic security, stability and independence of the state. In nature, the reserves of gold are not unlimited, but today large deposits of the precious metal are being discovered and developed.

What breeds are contained?

The main gold reserve of our planet is stored in the bowels of the earth. As a result of volcanic processes, gold with magma hit the surface and solidified in an alloy with other substances in rocks. The processes proceeded unevenly, therefore, the precious metal is not everywhere. The close location of gold is indicated by a large amount of quartz, granite and sulfide ores - pyrite, marcasite, pyrrhotite, ammonite and others.

There are two types of gold deposits.

- Primary or rootif gold is in rocks. Most often, the precious metal is included in small inclusions in the ore, from which it must be extracted. If it was possible to extract 5-7 grams of gold from a ton of stones by an industrial method, then this ore is considered gold, and if there is more, then the deposit is called a gold mine.

- Alluvial or secondary, when, under the influence of natural phenomena, stones are broken, grinded, and the gold grains included in them settle at the bottom of mountain rivers and lakes.

What does it look like?

In nature, gold does not look familiar to us and comes in different shades: from gray-green to red. Many rocks in placers look very much like a precious metal. Especially often it is confused with pyrite - pyrite.For this, pyrite was nicknamed "dog gold". It's pretty easy to identify a precious metal - it is necessary to draw a thin needle over the stone. If it's pyrite or some other mineral, it will crumble, but if it's real gold, it won't.

But not all stones that look like gold can be check by mechanical stress. In such cases, resort to chemical test method. To do this, the stone under study is immersed in sulfuric acid: during the reaction, the sulfides will darken, and no changes will occur with gold. There is also such a miracle of nature as pure gold - nuggets... They are obtained in the course of active leaching of gold-bearing sulphides, while the minerals are dissolved, and the precious metal remains.

The largest Russian nugget weighing over 36 kg was found in the South Urals in 1842.

How to get it?

For many centuries, mankind has been working on the problem of gold mining... In the Middle Ages, alchemists tried to obtain the "Philosopher's Stone", allowing them to turn ore into a noble metal. But their experiments were unsuccessful. Nowadays, modern technologies make it possible to extract the maximum amount of precious metal from gold ore. At refineries, the material is thoroughly processed, purified from impurities, flotation is performed with special reagents, pressed and dried in an oven. Subsequently, at the hydrometallurgical plant, the resulting concentrate is melted into gold ingots.

Our land keeps many mysteries and secrets. New deposits of precious metals are being discovered more advanced methods of refining are being developed... Gold still rules the world, so more and more people are striving to find stones with the cherished solar vein or nuggets.

You can also extract gold from stone at home. When choosing a method, the main properties of the precious metal are taken into account.

- Inertness prevents destruction under the influence of most acids and alkalis.

- High density and gravity provide maximum efficiency in separating precious metal from others with the oldest and simplest method of extraction - washing.

- Softness and plasticity make it possible to retain their properties even at ultra-low thicknesses.

- Under the influence of high temperatures, the noble metal melts and boils. When melted, liquid gold loses its density and evaporates long before it boils.

Knowledge of the basic properties helps to correctly isolate gold particles from a stone in a home laboratory and not lose a single grain at the same time.

There are several basic methods of refining.

Dry

Gold-bearing stones immersed in a special unit, resembling a mill, and carefully ground into a fine powder. The resulting mixture treated with gaseous chlorine... The ensuing chemical reaction allows the precious metal to be separated from the minerals, since it converts all non-metallic elements into a gaseous state. The dry method of refining requires strict adherence to all precautions.

Chemical

This method is often practiced by jewelers and amateur chemists, who extract gold elements not only from stones, but also from radio components, microcircuits, contacts and transistors. Chemical refining can be done using several reagents. The method is based on the peculiarities of the entry of metals and minerals into reactions with acids and alkalis.

The first step using saline or sulfuric acid all non-metallic elements are removed. At the second stage, a mixture of metals is dissolved in nitric acid with constant heating. The resulting composition is immersed in hydrochloric acid and nitric acid is periodically added dropwise. Then the mixture is evaporated to dryness and poured with an aqueous solution of ferrous sulfate. The resulting brown precipitate is boiled in concentrated nitric acid, while the last remnants of impurities are removed, and gold remains.

By electrolysis

Gold chloride is immersed in a transparent capacious container with a solution of hydrochloric acid and an electric current is connected. During the reaction, there is a gradual drop in current strength. This means that the oxidation process has ended and the precious metal is completely purified.

With tin chloride

Water and hydrochloric acid are poured into the vessel in equal proportions, tin chloride powder is added. Crushed gold-bearing stones are immersed in the resulting solution. After about a day, the formed precipitate is filtered and boiled in hydrochloric acid for complete purification of impurities.

Flushing

For a long time, one of the easiest and safest ways to mine gold is flushing... In the shallow waters of mountain rivers, sand from the bottom is passed through a sieve, while particles of precious metal remain on the mesh, and less heavy impurities are removed by a stream of water.

In ancient Greece and the Caucasus, sheepskin was used for gold mining.... It was fixed in a special way at the bottom of the river. Under the onslaught of water, small grains of sand easily penetrated the skin, while heavy grains of gold remained on the wool. Gradually, the white fleece became completely golden. It is not in vain that the Argonauts from the ancient Greek myth put so much effort into their search for the golden fleece.

In those days, the noble metal was not only a symbol of wealth, but also the absolute power of the country.

Miller's table

It is possible to separate gold from stones and sand by washing at home. For this it follows buy or make a Miller table - a special box 25 cm wide and 50 cm long. A hard mat is placed on the bottom. The test material (sand, finely crushed stones) is loaded into the box and washed under a constant stream of water. As a result, light grains of sand and particles of minerals are washed away, and heavier gold grains settle on the rug.

In Russia, prospectors are allowed to extract precious metal from spent mines and small placers. To do this, you need to purchase the appropriate license.

Security measures

When working with acids and alkalis, safety rules must be observed. Reagents falling on open skin areas cause chemical burns. It is important to remember that when they evaporate, they emit poisonous gases that are hazardous to human health and can damage the organs of vision and respiration.

All work should be carried out in a well-ventilated area with an exhaust hood and personal protective equipment should be used - rubber gloves, a mask, overalls.

The following video presents one of the most effective ways to get gold from a rock.