How to get gold?

Gold can be mined not only on an industrial scale, using sophisticated equipment. You can also feel like a gold miner at home if you get the right starting material and familiarize yourself with some of the chemical processes.

Features and legality

Getting gold at home can carried out only with an appropriate license. Moreover, it is issued only to a legal entity registered at a legal address. If a person just wants to get gold in his apartment, then he will thereby violate the Criminal Code.

The advantages of independent gold mining include the absence of high costs for both the starting material and reagents, as well as the simplicity of the process itself.

By mining the precious metal in this way, you can make good money in a short time. Undoubtedly, there are also shortcomings in the activity. For example, the reactions produced are not safe, and finding enough starting material can take a lot of time and effort. Again, legalizing home gold mining takes a lot of effort.

Where can you get gold?

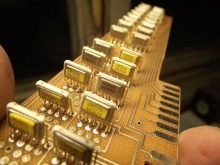

As a starting material for obtaining gold, completely ordinary items, most often available in the household, are suitable. For example, you can use old phones, microcircuits, computers and radio tubes - that is, any devices with radio components - both from radio engineering and from electronics. However, it is important that they were issued a long time ago, since it was in Soviet times that a sufficient amount of gold was used to create radio components, which means that it will be possible to extract it.Thus, it turns out that the older the device is, the more it will "give out" the precious metal.

Of modern devices containing radio components, SIM cards and laptops are used to obtain gold.

A fairly traditional solution is use of household items with gilding, for example, jewelry, cutlery or decorative items. However, this starting material gives a small amount of gold, because initially the precious metal is applied in a very thin layer. On the contrary, a good "catch" is obtained when processing old capacitors, containing not only gold but also silver.

For example, a capacitor, the dimensions of which are close to a three-liter can, makes it possible to extract 8 grams of gold and about 50 grams of silver.

It is recommended to sort all workpieces beforehand. First, they are laid out in size, and then all unnecessary elements are removed from their surface to save time and chemicals. At the final stage of preparation, you will have to sort the parts using a magnet. It is important to form a bunch of those elements that react to it, and those that do not attract at all. The sorting process significantly saves on the chemicals used in the future.

It is also possible to obtain a precious powder from sand and clay, but this process is very laborious. Again, difficult, but you can try to extract gold from mercury, silver and lead.

Production methods

In fact, there are a fair number of ways to mine gold, but at home, it is customary to use two of them: electrolysis and etching. Each method has both advantages and disadvantages. Carrying out electrolysis is more laborious, but less reagents are required to implement it.

Both methods require safety precautions in order not to get a chemical burn. It is best to work in a well-ventilated area.

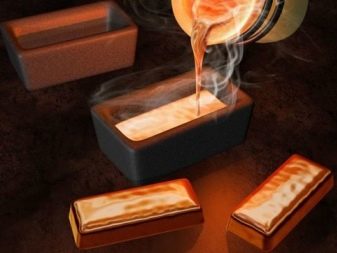

The resulting gold can be used to repair jewelry, restore, solder parts or, in the case of high quality, to make new decorative items. The easiest way to use at home is casting methodwhen the heated metal is poured into a casting mold in a thin stream. To make the metal look more attractive, its surface is polished with a felt cloth, on which ordinary toothpaste is applied. Jewelry solder for brazing is made by mixing gold with additives.

In all cases, it is important to remember that earning income from independent gold mining is only possible with an appropriate license.

Etching method

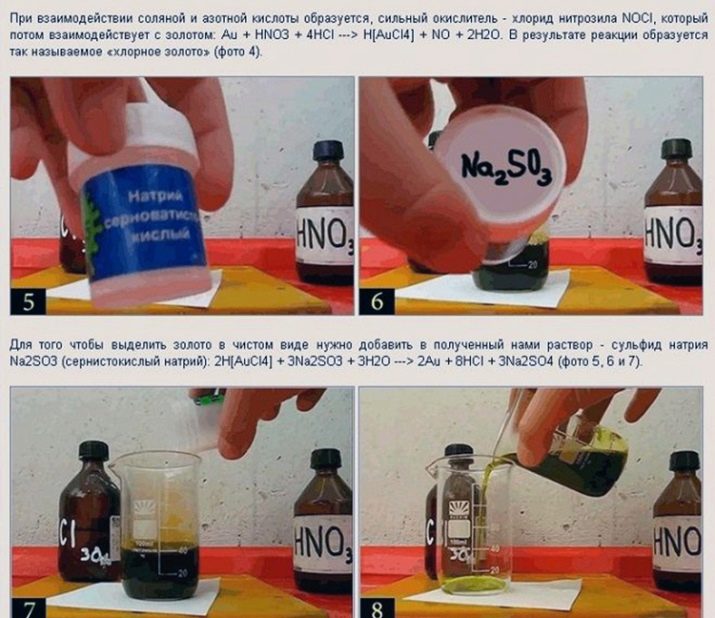

Having given their preference to the etching method, it will be necessary to prepare plastic basin and bucket, scales, glass vessel resistant to high temperatures, as well as a refractory crucible or its equivalent required for melting metal. Durable cotton flap fabrics will adequately cope with the task of filtration, and rubber gloves provide the necessary protection for your hands. Of course, for the entire procedure, you will need electric stove. By the way, in the absence of a crucible, you can replace it with a piece of burnt brick, in which a recess is created with the help of a Bulgarian saw. Since gold, being a chemical element, has a high inertness, to activate etching a certain oxidizing agent is required.

Experts recommend using for this purpose a mixture of hydrochloric and nitric acid, combined in a ratio of 1 to 3... This solution, by the way, is popularly known under the name "aqua regia". The oxidizing agent should be used as soon as it is prepared, as delay will trigger the settling process, which, in turn, promotes the decomposition of nitrogen dioxide.Visually, this can be determined by noticing how the transparency of the liquid changes to a light yellow tint. As a result, the oxidizing agent starts to function much worse, and the process of gold synthesis becomes less effective.

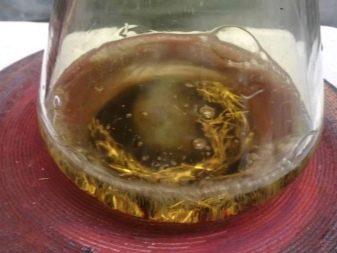

The whole process consists of dipping boards, microcircuits and other parts into a solution, as a result of which gold particles form a thin film on the surface. Some experts also recommend to warm up the liquid somewhere up to 70-80 degrees Celsius. You should be prepared for the rest of the starting material to completely dissolve. By the way, in the case when gold needs to be precipitated, iron vitriol, hydrogen peroxide or oxalic acid can be added to the "aqua regia". At the end of the procedure, the liquid is filtered using a cotton cloth. If everything is done correctly, then a layer of gold will remain on its surface.

Before starting work, it is important to ensure that the nitric acid is of high purity and does not contain any impurities. It is easy to check the quality of the substance - if smoke appears when you uncork the bottle, then the product is clean.

Melting of the appeared gold particles occurs in a crucible using borax. As a rule, the crucible is heated on an electric stove or with a burner, after which the heated metal is poured into a mold in a thin stream. Such gold is stored in a dark place where the sun's rays do not fall. In the room, it is important to avoid excessive humidity, as well as temperature fluctuations.

To prevent the gold from evaporating during etching, it is advised to supplement the acid mixture with a small amount of common salt. Typically, 10 milliliters of mixture requires 0.2 grams of grains. You need to add salt during evaporation - that is, periodic heating to a temperature of 70-80 degrees. A combination of boiling water and 2 milliliters of hydrochloric acid added to the solution will work in a similar way.

By electrolysis

Another common way to get gold at home is electrolysis... It is suitable in cases where microcircuits, SIM cards, semiconductors or similar parts are used as a source material. Electrolysis is more difficult than etching, but gold is also cleaner. In addition, it is possible to obtain the precious metal from lead. The work begins by filling a suitable vessel with either hydrochloric or sulfuric acid.

Several plates made of iron or lead are lowered into the liquid. The essence of electrolysis will be that it is they who will become the cathode, and the parts of gold that are in SIM cards and other processed parts will be in the role of the anode. Using a copper wire, the cathode plates must be connected to each other, and then to the electrical network. The electrical power should be approximately 0.8 amperes per square decimeter. By running the electricity, you can gently dip the prepared parts into the acid. After the gold has moved to the cathode, it is necessary to turn off the current and remove the plates.

During work, it is important to observe safety rules and use rubber gloves, an apron, eye protection and a respirator.

For information on how to mine gold at home, see the next video.