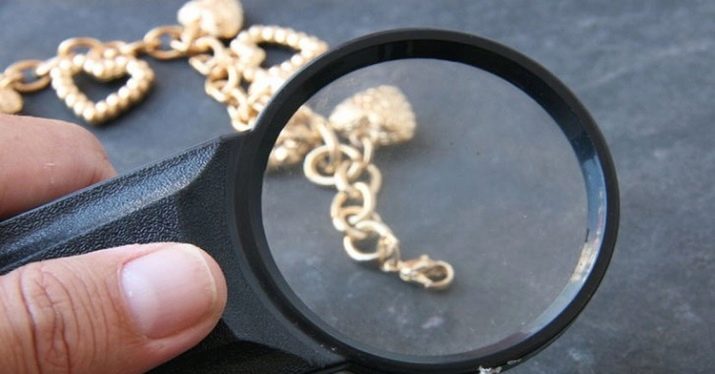

How to remove gilding?

In the house of almost every person there are items with gold plating - gilding. But probably not everyone knows that you can remove gold even at home, using a certain procedure and components.

Wear life of gold plated

In Russia, in order to coat a product with gold plating, precious metals are used, the fineness of which is not lower than 750. As a rule, 999 is used. Sometimes you can encounter 585 spraying samples. According to experts, in order for the gilding to be applied with high quality, an item made of 925 sterling silver is required. The applied gold must be at least 42% and the coating thickness must be at least 2.5 microns. If these conditions are met, the gilding will last the maximum period.

If you look at the product, outwardly it is impossible to distinguish it from gold. But gilding is not suitable for everyday wear, because with mechanical stress the coating can be erased. Some people mistakenly believe that gilding will wear off when it comes in contact with water, but this is not the case. Only scratches can destroy the surface. All this suggests that the wear life depends on careful storage and wear. If the gilded item was bought in a jewelry store and has the necessary quality certificates, then the jewelry will delight its owner for 2 years or more.

It should be borne in mind that pendants and earrings, which rarely come into contact with the skin, will be worn even longer.

Withdrawal methods

Gilding can be removed from silver and independently. There are two ways to do this:

- chemical;

- electrochemical.

Chemical

This method requires the presence of "aqua regia" (solvent).The process is delicate, because it involves removing the gilding without dissolving the base. Before starting work, you need to clean the products to a shiny state. A similar method can be used for coins, when removing from dishes and other products that you have to work with.

How to proceed.

- The warmed-up item should be placed in a porcelain cup filled with aqua regia solvent.

- Then the bowl should be heated in a sand bath. It is not necessary to bring to a boil. If you use this method of processing, the gilding will begin to slowly be removed.

- Objects are removed as soon as dark spots begin to appear on the surface.

- Now the product should be rinsed in water.

- To remove silver chloride that appears as dark spots, you should briefly immerse objects in an ammonia solution.

- The remaining gilding must be removed with a brush.

Electrochemical

This method is relevant for coins. In it, the product is placed in an electrolytic bath and acts as an anode. A copper plate is used as a cathode. The electrolyte is made by adding a solution of calcium cyanide (7%) to distilled water. When the coins have been processed, they are removed from the bath and rinsed under running water. The remaining gilding can be removed from the metal with a brush.

With radio components

You can remove gilding from radio components at home using an electrolyte with nitrate. To work, you will need an electrolyte for the battery, as well as a choice of ammonia, potassium or sodium nitrate. When working with ammonium nitrate, you should use a bucket of mayonnaise or any other nylon container (with a lid), the volume of which is about half a liter. A hole of 3 mm must be made in the lid. 200-300 grams of electrolyte and 100 grams of nitrate are poured into a bucket. The ingredients are mixed until the saltpeter dissolves. Now you can put in the container parts that were previously cleaned of iron. The bucket is heated in a water bath.

You can boil a saucepan and place a container in it. While the water is boiling, the parts react with the liquid, as a result of which brown gas will escape through the hole. You need to work with gloves and a ventilated room. Do not inhale vapors. As soon as the reaction has begun, the bucket is removed and placed in a cool place. The hiss may continue or even intensify - this is normal. It will last about 30 minutes, after which all the gold will turn into a film on the surface of the liquid. Now you can dilute the solution with water and filter. For this purpose, you can use matter folded in several layers. The resulting gold is dried and can be used for further purposes.

From other subjects

There is a safe and easy way to easily remove gold plating from telephone SIM cards, processors, microcircuits, boards. For work, you should prepare the following.

- A couple of glass jars. Alternatively, you can use trays.

- Thick fabric.

- Fine fraction salt.

- Vinegar. If not, citric acid and hydrogen peroxide can be substituted.

Five small spoons of salt are placed in a jar, diluted with vinegar, in an amount of 50 ml. Then add 100 ml of peroxide. All ingredients are mixed. Now you can put SIM cards in the bank. In a minute, a reaction will begin. Salt should be added every 10 minutes, but no more than 9 teaspoons in total. When the reaction is over, gold particles will remain on the surface, which should be filtered through a cloth.

Important! This method is not very efficient for boards.

You can separate the gilding with ordinary pharmaceutical iodine. The method is relevant for radio components. You will need 1.2 grams of crystalline iodine, 4 grams of potassium iodide, 50 ml of ordinary water. All ingredients are mixed, after which 0.7 ml of nitric acid is added. Now you need to take 10 ml of iodine, you can add radio parts. All components are mixed.After 15 minutes, the solution must be drained into another container. In such a short period of time, the solution will have time to dissolve the spraying.

Now it remains to besiege the gilding. To do this, you can use an alkaline solution, for example, sodium sulfite (2 teaspoons), diluted with 20 ml of water. This mixture is poured into a reagent. You need to pour it gradually, as the mixture actively hisses and splashes. All components are stirred, and when the reaction is over, gold will settle at the bottom.

You can also dissolve gold in sulfuric acid. You will need the concentrated sulfur solution itself, glassware, a 5A power supply (minimum). Lead acts as a cathode, and the product itself acts as an anode. First, sulfuric acid is poured into the dishes. The minimum amount of solution is taken by eye, because then it will need to be diluted. We place the anode, cathode and power supply in the liquid and turn on the voltage. A reaction will immediately begin, during which the liquid will darken.

Important! The optimal voltage in this case is 12-14 Volts.

When the current begins to decrease, it means that you can pull out the products. Now you should again dilute the sulfuric acid and filter it several times until the solution stops being cloudy. Products should be placed in water and it is also recommended to rinse, because there will also be gilding. If you need to wash off the gilding from the levkas, you can use a scalpel with a waterproof skin for this purpose. It allows you to separate the residues from the surface. The top layer of varnish can be carefully removed with a router or drill.

Precautionary measures

When removing gilding, you need to remember about your safety. When resorting to the electrolysis method or another method, you need to work with gloves and in a well-ventilated area. Avoid skin contact and eye contact. Wear a respirator to avoid inhaling harmful vapors. Ingestion of substances is also prohibited.

Tips & Tricks

You can get gilding from almost any gilded object. If there is a protective coating on the product in the form of varnish, this layer is initially removed with acetone, alcohol or a concentrated solution of sulfuric acid.

To be sure of the presence of gold on the part, you can look at the component's data sheet. The percentage will also be indicated there.

In the next video, you will see the removal of the gilding from the gilded radio elements of the USSR.