All about rhodium plating

From time immemorial, jewelry was considered a sign of wealth or even luxury. A well-chosen accessory indicated the excellent taste of its owner. Nowadays, gold jewelry is a wonderful gift for both young girls and adult women. Don't forget about luxurious presentations for men. To give the yellow metal an expressive appearance, experts use special coatings.

What it is?

At the peak of popularity are jewelry, in the manufacture of which the technology of rhodium plating of gold was used. During this procedure, the product is coated with another metal - rhodium.

Rhodium plating is used when working with jewelry of various samples, including 585, which is the standard for most jewelry.

As a result of processing, the yellow material acquires a light shade and becomes similar to white gold.

Rhodium belongs to precious metals and is included in the metals of the platinum group. It has all the necessary physical and chemical properties. It is a solid and inert element included in the periodic table. In addition, experts noted the high reflectivity of rhodium, thanks to which jewelry acquires an expressive shine and radiance.

The substance used to treat jewelry was discovered in 1803. Due to the small number of deposits of this metal, its value is constantly increasing.

The light and shining coating serves not only a visual, but also a practical purpose. Do not forget that although gold is a beautiful metal, it is naturally soft.

With a slight load, it deforms, scratches and other defects appear on it.

Rhodium plating makes the product stronger, removes excessive plasticity.

Rhodium plating is used for the following purposes:

- changes in the color shade of the product;

- shading decoration;

- strengthening the fastener;

- processing of places intended for inlaying the product with stones.

Advantages and disadvantages

Rhodium plating has its own advantages and disadvantages, which have been identified by jewelry connoisseurs and professional goldsmiths.

This procedure has a number of positive characteristics.

- Platinum group metal treatment gives the products a unique appearance. Rhodium-plated jewelry becomes more radiant, expressive and noble. In addition, this appearance is retained even with intensive use of jewelry.

- If you want to preserve an antique piece of precious metal, it is recommended to take it to a jewelry workshop by ordering a rhodium plating service. Such processing will change the chemical characteristics of the metal, and due to this, the service life of the products will be significantly extended.

- A layer of noble and light metal makes the products less vulnerable to negative environmental influences, for example, to temperatures and various reagents. Processed products are not afraid of alkali, acids, chlorine and other aggressive components. This factor is important for those who wear jewelry almost always.

- With the help of rhodium, specialists change the standard color of gold. In most cases, when using platinum group metal, a glossy white tint is achieved on the surface of a gold jewelry. However, with the help of additional chemical elements, you can give the product another unusual shade.

- Through processing, you can refresh old jewelry, giving them a modern look. This is a low-cost service that is affordable for everyone.

The main advantages related to the use of rhodium in the jewelry industry are listed. In fact, there are many more advantages of such processing. Despite its many advantages, this procedure has its drawbacks.

The cons are as follows.

- Changing the appearance of a product is considered both an advantage and a disadvantage at the same time. The fact is that due to rhodium, it is difficult to visually identify the metal from which the jewelry is made. Some buyers who pay special attention to jewelry can determine the fineness of gold by eye. But not all users are able to do this. In order not to become a victim of scammers by spending money on a fake, you need to make a purchase in a trusted store. It is also recommended to check the documentation that comes with each piece of jewelry.

- Another disadvantage is that the coating is rubbed off. Despite the strength and wear resistance of rhodium, a thin layer is applied to the products during processing, which wears off over time. In this case, you will have to constantly update the coverage, and this is an additional financial cost.

The visual effect of processing and its service life depends on the craftsman performing the work and other factors.

The rhodium layer can be of various thicknesses, ranging from 0.1 to 0.25 millimeters.

The wear resistance, practicality and resistance of the additional layer to external influences depend on this parameter.

Technology

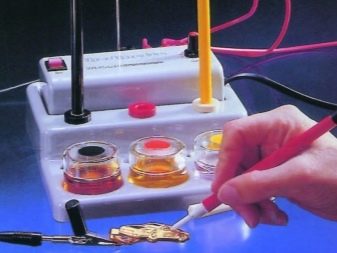

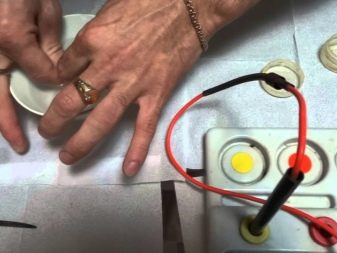

Nowadays, jewelry professionals use several rhodium plating technologies. During this process, electrolysis is used.

This is a special physicochemical process that requires special skills and abilities.

Before rhodium plating, you need to prepare jewelry. They are thoroughly cleaned with special solutions and polished. Then degreased with alkali and washed - successively in hot and cold water.At the final stage of preparation, the products are kept for several seconds in a sulfuric acid solution. This is done to improve the adhesion of rhodium to the gold surface.

At the same time, a liquid solution of rhodium salts is being prepared. The products are immersed in a liquid bath through which an electric current is passed. During the processing, the molecules of this platinum metal form an even and smooth layer.

The maximum coating thickness is 25 micrometers. This indicator is 4 times less than the thickness of a human hair.

White gold plating

When using rhodium for processing white metal products, an additional layer is applied over the entire surface of the product. This is because the base alloy is the same color as the protective coating. Even if the top layer is erased or damaged, the difference will not be noticeable. In some cases, when working with light precious metals, rhodium plating is used for protective purposes.

Yellow and red gold processing

In this case, the craftsmen adhere to the same technology as when working with white gold. The main difference lies in the partial application of rhodium to the surface of the product. The fact is that over time, the base metal will gradually begin to show through the additional layer. As a result, the appearance of the jewelry will deteriorate, the aesthetics will be violated.

When working with non-ferrous precious metals, only the bed for stones is coated with rhodium, increasing their reflectivity. After processing, the brightness of the radiance is significantly increased.

Rhodium plating is very similar to the gilding process. In both cases, a thin layer of metal is applied to the product, which changes the appearance of the product and acts as a protection. The main difference is that the rhodium layer is white, while the gilding is yellow.

Varieties of processing

Rhodium plating is used for several purposes. There are several types of coating that have been used by professionals for more than a decade.

Standard processing is used in most cases. With its help, products acquire a cold shine and a silvery shade. The coating lasts a long time, extending the service life.

This type of coating is used when working with gold, silver and even jewelry.

Black rhodium plating

In this case, the usual protective properties of the metal layer are retained, while the objects receive a noble and sophisticated blackness. With the help of such processing, the products acquire an antique look. The wizard can adjust the saturation of the coating from light gray to deep black. This processing option is perfect for items with black stones or pearls. The original effect is achieved due to the special chemical composition.

Jewelry care

Rhodium plated products require careful and regular care. And although rhodium increases the strength and durability of jewelry, it is still a thin layer of coating that wears off over time.

To keep rhodium-treated items looking presentable, the plating should be periodically refreshed.

The basic rules with processed products are in several points.

- Store jewelry in a separate box or case.

- Despite the resistance of rhodium to chemical compounds, it is advisable to protect jewelry from contact with reagents.

- Before going to bed, cleaning, applying cosmetics and using household chemicals, products must be removed.

- Rings are especially prone to abrasion. As soon as they lose their presentable appearance, they should be taken to a jewelry workshop.

- It is recommended to periodically clean the products. The work should be carried out without the use of aggressive or abrasive substances. You can use a soft cloth or brushes.

See the following video for the benefits of rhodium plating.